Release Date:2023-09-19 10:41:16 Popularity:

Fully automated packaging machines have become an indispensable part of the modern production process. This efficient equipment can greatly improve production efficiency, reduce labour costs, improve product quality and extend product shelf life, so it has been widely used. This article will introduce the working principle of fully automatic packaging machine, application scenarios and development prospects.

First, the working principle of fully automatic packaging machine

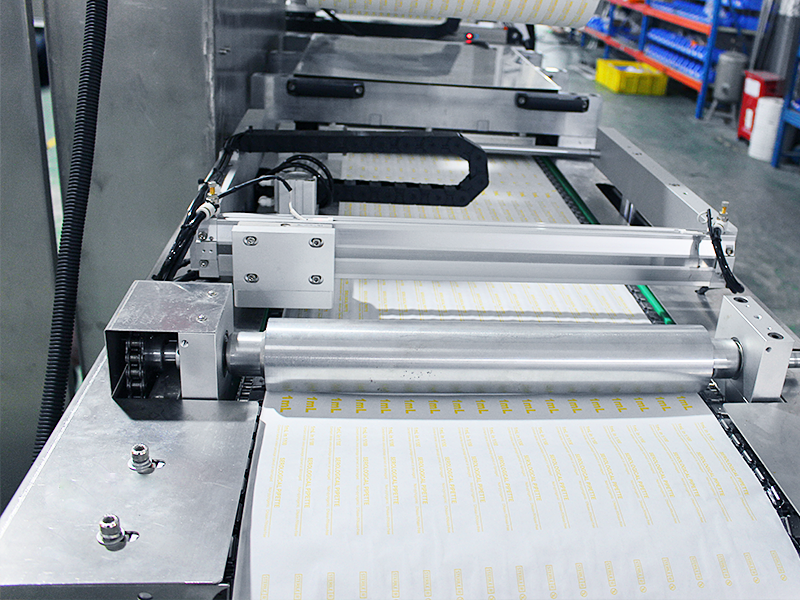

Fully automatic packaging machine mainly includes the following components: mechanical system, control system, pneumatic system and packaging materials. The mechanical system is the core of the packaging machine, which includes the conveying device, weighing device, encapsulation device and so on. The control system is responsible for the coordination and control of the whole packaging process, including the input and output system, touch screen interface and so on. The pneumatic system provides power for the mechanical movement, and at the same time ensures the cleanliness and hygiene of the equipment. Packaging materials, on the other hand, are selected according to the different requirements of the products and different materials and specifications.

The workflow of the fully automated packaging machine can be briefly described as follows: the product enters the packaging machine through the conveying device, passes through the weighing device for weight detection, and then enters the encapsulation section. In this process, according to the preset programme, the machine will automatically identify the type, quantity and other information of the product and pack it accordingly. Finally, the finished packaged products will be output through the conveying device.

Second, the application scene of fully automatic packaging machine

Fully automatic packaging machine is widely used in many industries such as food, medicine, daily chemicals and so on. In the food industry, such as the packaging of snacks like biscuits, candies, chocolates, etc., as well as the packaging of grains like rice, flour, etc., the fully automatic packaging machine can improve the production efficiency and ensure the hygiene and quality of food. In the pharmaceutical industry, fully automated packaging machines can ensure the accurate dosage of medicines and improve the safety and effectiveness of medicines. In the daily chemicals industry, fully automated packaging machines can provide a cleaner, more hygienic production environment while improving product quality and added value.

However, despite the many advantages of fully automated packaging machines, there are some disadvantages. Firstly, the cost of the equipment is high, and for some small businesses, investing in a fully automated packaging machine may bring some financial pressure. In addition, due to the large size of the machine, it needs to occupy more production space. Furthermore, the maintenance and commissioning of the equipment requires professional and technical personnel, which also brings certain challenges to the operation of the enterprise.

Third, the development prospects of fully automated packaging machine

With the continuous development of science and technology, fully automated packaging machines are also constantly upgrading and improving technology. In the future, the fully automated packaging machine will be developed in the following directions:

High precision: through the introduction of more accurate sensors and control systems to improve the accuracy and stability of the packaging machine to meet higher standards of product packaging requirements.

Intelligent: using artificial intelligence, Internet of Things and other technologies to achieve remote monitoring, fault diagnosis, energy management and other intelligent functions of the packaging machine, to improve the operational efficiency of the equipment and production management capabilities.

Sustainable: focusing on environmental protection and energy saving, adopting environmentally friendly materials and energy-saving technologies, reducing energy consumption and waste emissions of equipment, and realising green production.

Flexibility: with stronger adaptability, can cope with different types and specifications of product packaging requirements to meet the diverse needs of the market.

Comparing the development status of fully automated packaging machines at home and abroad, there is still much room for improvement of domestic packaging machines in terms of intelligence and sustainability. In the future, domestic enterprises need to further strengthen technological research and development and innovation, in order to promote the overall development level of fully automatic packaging machine.

As an indispensable part of the modern production process, fully automated packaging machine has the advantages of improving production efficiency, reducing labour costs and improving product quality. However, there are also shortcomings such as high equipment costs and large space occupation. In the future, fully automated packaging machines will develop in the direction of high precision, intelligence, sustainability and flexibility. Domestic enterprises need to pay attention to these development trends, strengthen technical research and development and innovation, in order to improve the overall development level of fully automated packaging machine, to better meet the market demand at home and abroad.