Release Date:2023-07-08 10:35:22 Popularity:

With the improvement of people's health awareness and the continuous improvement of living standards, bottled water, as a convenient, safe and healthy form of drinking water, has been favored by more and more consumers. As the key equipment in the bottled water production line, the fully automatic bottled water filling equipment has become an ideal choice for many bottled water manufacturers to maximize production efficiency due to its high efficiency, precision and reliability. This article will introduce the concept and working principle of fully automatic bottled water filling equipment, discuss its impact on production efficiency and product quality, and focus on demonstrating its advantages in improving production efficiency and ensuring hygiene and safety.

A. Concept and working principle of automatic bottled water filling equipment

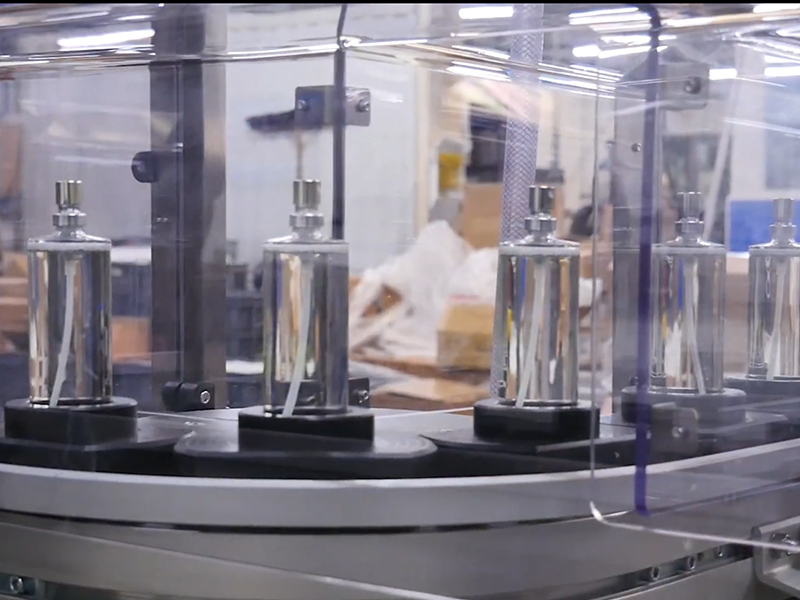

Fully automatic bottled water filling equipment refers to a production line that realizes a series of operations such as filling, sealing and labeling of bottled water through automated equipment and systems. It usually consists of multiple components such as conveying system, filling machine, sealing machine, marking machine and control system. Fully automatic bottled water filling equipment can realize bottled water filling of different specifications and capacities according to different production needs, so as to meet the diverse needs of the market.

The working principle of automatic bottled water filling equipment mainly includes the following steps:

1. Bottled water delivery: The empty barrels are transported from the storage area or the previous process to the filling area through the delivery system.

2. Filling: When the empty barrel reaches the filling area, the automatic filling machine will automatically measure and fill the barreled water, and control the accuracy of the filling volume.

3. Sealing: After the filling is completed, the automatic sealing machine will automatically seal the mouth of the barrel to ensure the tightness, hygiene and safety of the bottled water.

4. Marking: After the sealing is completed, the automatic marking machine will affix the necessary information such as the corresponding trademark and production date on the barrel to provide effective traceability management for the product.

5. Transportation and storage: The bottled water that has been filled passes through the transportation system and is sent to the storage area or the next process for further processing and packaging.

B. Advantages of automatic bottled water filling equipment

1. Improve production efficiency: The automatic bottled water filling equipment can complete the filling operation quickly and continuously, greatly improving production efficiency. Compared with the traditional manual filling method, the automatic bottled water filling equipment can save a lot of human resources, and in the case of 24-hour continuous operation, there is almost no need for downtime maintenance, and the production efficiency is higher.

2. Guarantee hygiene and safety: the fully automatic bottled water filling equipment has a high degree of hygiene and safety performance. The equipment is made of food-grade materials and complies with relevant hygienic standards, which can effectively avoid the influence of human factors on the hygienic quality of bottled water. In addition, the equipment is also equipped with an automatic cleaning and disinfection system to ensure the sanitation of the equipment and pipelines before each filling.

3. Flexible and diverse adaptability: the automatic bottled water filling equipment can adapt to the bottled water filling needs of different specifications and capacities. Through simple adjustment and replacement of filling parts, the filling of barrels of different sizes can be realized, providing greater production flexibility and market adaptability.

4. Data management: The automatic bottled water filling equipment is equipped with advanced control system and data acquisition technology, which can realize real-time monitoring and recording of information such as filling process, measurement data and equipment status. These data can be used to provide production reports, quality analysis and management decisions to further improve the level of production management.

C. The future development trend of automatic bottled water filling equipment

1. Intelligent: With the continuous development of artificial intelligence technology, automatic bottled water filling equipment will become more intelligent. For example, through image recognition and machine learning algorithms, the automatic detection and adjustment of the bottled water filling process can be realized, the filling accuracy and stability can be improved, and the waste in the filling process can be minimized.

2. Automatic line adjustment: Future automatic bottled water filling equipment will pay more attention to the automation of line adjustment. Through the sensor and automatic control system, the liquid level and pressure of each filling point are monitored, and the filling flow is automatically adjusted to ensure the consistency of each bottled water.

3. Energy-saving and energy-saving: the design of automatic bottled water filling equipment will pay more attention to energy-saving and environmental protection. For example, energy-saving motor drive systems, waste water recycling systems, and energy-saving conveying systems are used to reduce energy consumption and environmental pollution and achieve sustainable development.

4. Robot collaboration: Future fully automatic bottled water filling equipment will pay more attention to robot collaboration. Through the application of intelligent robots, operations such as automatic bottled water extraction, filling and sealing can be realized, reducing manual intervention and improving production efficiency and safety.

Fully automatic bottled water filling equipment has become an indispensable part of the bottled water production line due to its high efficiency, precision and reliability. It plays an important role in the production process of bottled water by improving production efficiency, ensuring hygiene and safety, flexibly adapting to market demand and data management. In the future, fully automatic bottled water filling equipment will be more intelligent, automated, energy-saving and environmentally friendly, and robot collaboration will provide bottled water production enterprises with more efficient and sustainable filling solutions. It is believed that with the continuous advancement of technology, fully automatic bottled water filling equipment will surely promote the development of the bottled water industry and meet consumers' needs for high-quality and safe bottled water.