Release Date:2025-04-01 14:30:31 Popularity:

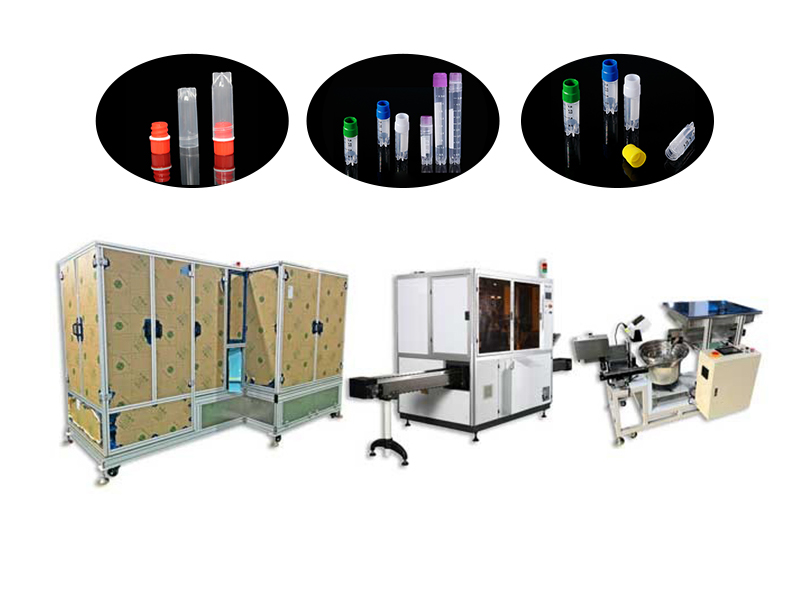

As a commonly used consumable in the fields of biomedicine, scientific research and medical testing, cryopreservation tubes are widely used for the preservation and transportation of biological samples, cells, blood, vaccines and genetic samples. The traditional production of cryopreservation tubes mainly relies on manual assembly and packaging, which is not only inefficient, but also has large errors in cleanliness and consistency. In order to meet the requirements of batch, high precision and aseptic production, the automatic production line for cryopreservation tubes has emerged. This kind of production line realizes automatic injection, filling, capping, marking, testing and packaging and other whole process automation, which greatly improves the production efficiency and product quality, and has become an indispensable intelligent manufacturing equipment in the field of biomedicine.

The automatic production line for cryopreservation tubes is a kind of intelligent production equipment integrating injection molding, automatic assembly, labeling and marking, encapsulation and testing. Through automated control and high-precision inspection system, the production line realizes efficient production and precise assembly of cryopreservation tubes, ensuring that the products comply with medical standards and GMP norms. The whole line can realize unmanned continuous operation, which can effectively improve production capacity and quality consistency.

I. Workflow of the automatic production line for frozen storage tubes

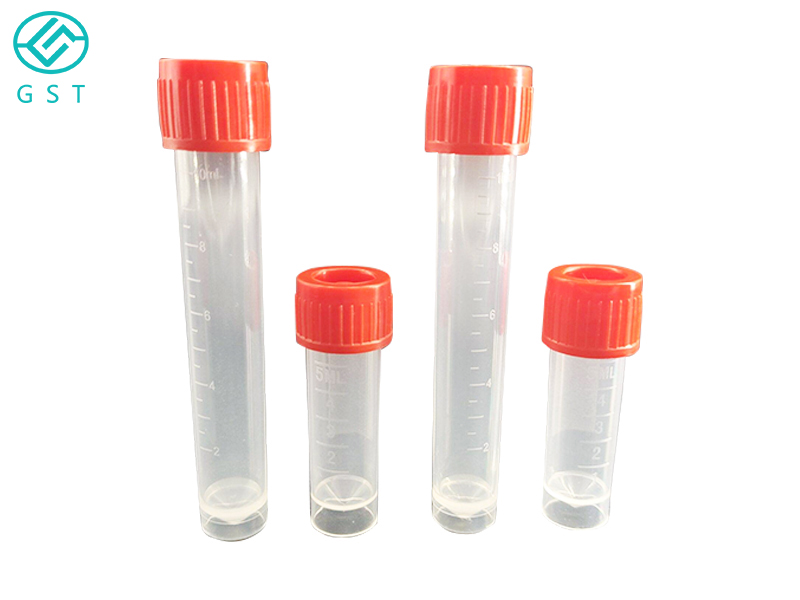

1. Injection molding: Medical grade polypropylene (PP) or polycarbonate (PC) raw materials are fed into the injection molding machine. It melts under high temperature and molds the frozen storage tube body at one time through the mold, with precise dimensions in line with medical standards. Automatic cutting of the tube opening ensures flat and smooth edges without burrs.

2. Automatic loading and sorting: Through the automatic loading device, the cryopreservation tube body and cap are automatically sorted to the assembly station. Vibrating disk or conveyor belt will accurately align the tube body and cap to ensure smooth assembly process. Multi-channel loading can be realized to handle many kinds of frozen storage tubes at the same time.

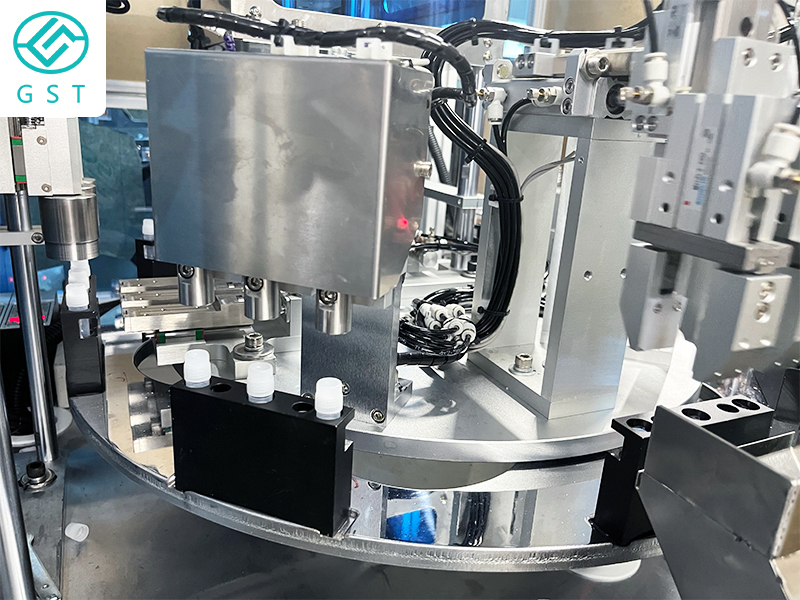

3. Automatic assembly and capping: robot or automatic fixture will automatically assemble the frozen storage tube and cap. According to the process demand, it can realize capping, capping or heat sealing to ensure the sealing. Multiple stations work in parallel to improve production efficiency.

4. Coding and labeling: online printing of batch number, two-dimensional code or barcode to realize product traceability management. Automatic labeling machine accurately affixes labels to tubes or caps in a standardized and consistent position. Comply with pharmaceutical grade waterproof labeling standard, low temperature and abrasion resistant.

5. Detection and Rejection: Visual inspection system is used to detect whether there are scratches, cracks or deformations in the appearance of the frozen storage tube. Laser sensor detects the sealing of the lid and labeling position to reject unqualified products. Automatically reject the defective products to ensure the rate of finished products and quality pass rate.

6. Automatic packing and counting: The qualified frozen storage tubes are automatically loaded into trays or plastic bags according to the set quantity. Automatic sealing and batch marking, convenient for subsequent logistics and management. It can be linked with automatic cartoner or palletizer to realize automatic production of the whole line.

Second, the advantages of automatic production line for frozen storage tubes

1. High-efficiency production, increase production capacity: automated production line can realize 24-hour uninterrupted operation, significantly increase production. The daily output of single line can reach hundreds of thousands of pcs or more, which can meet the demand of mass production. Multi-station parallel operation shortens the production cycle.

2. High precision, consistent quality: automatic assembly and inspection with high precision, error less than 0.1mm, to ensure product consistency. Prevent the risk of error and pollution caused by manual operation. Product qualification rate can reach more than 99.9%.

3. Reduce labor cost and improve efficiency: the whole line realizes unmanned operation and only requires a small number of personnel to monitor and maintain. Save a lot of labor costs and reduce human error. Improve the production efficiency and competitiveness of enterprises.

4. Comply with medical standards and clean requirements: the equipment is made of 304 or 316L stainless steel, in line with GMP and FDA specifications. The production environment can be kept dust-free and bacteria-free, suitable for medical grade consumables manufacturing. The product is pollution-free and meets the standard of medical cryopreservation.

As an important automated equipment in the field of pharmaceutical and laboratory consumables manufacturing, the automatic production line of cryopreservation tubes meets the strict requirements of pharmaceutical, scientific research and testing organizations on the quality and capacity of cryopreservation tubes by virtue of its high-efficiency production, precise assembly and intelligent testing functions. With the rapid development of biopharmaceutical and genetic testing industry, the automatic production line for cryopreservation tubes will continue to help enterprises to improve production efficiency and market competitiveness.