Release Date:2025-03-22 14:32:24 Popularity:

In the modern packaging industry, the capping process is an important link to ensure product sealing and appearance integrity. Traditional manual capping is inefficient and prone to uneven tightening or loosening problems, affecting product quality and packaging consistency. In order to improve production efficiency and packaging accuracy, automation equipment has gradually become the mainstream of the industry, in which the automatic capping machine with high efficiency, precision and stability, widely used in food, beverage, pharmaceutical, daily chemical and other fields. This equipment can automatically complete the bottle cap transportation, tightening and testing, effectively improve packaging efficiency and ensure product quality.

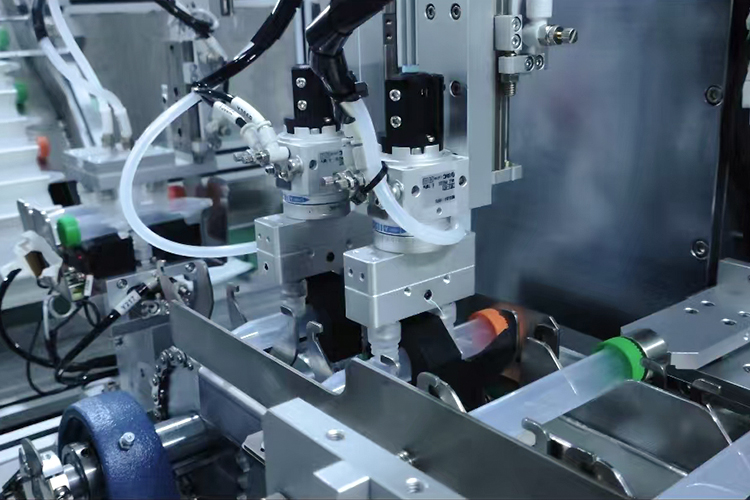

I. Definition and working principle of automatic capping machine

1. Definition: Automatic capping machine is a kind of packaging equipment used for automatic tightening or screwing of bottle caps, which can automatically complete the process of cap management, capping, screwing and testing of bottle caps. It is suitable for different types of bottled products such as round bottles, square bottles, shaped bottles, etc. The capping torque and speed can be adjusted to ensure the sealing of the cap and the consistency of the product appearance.

2. Working principle. The working process of automatic capping machine includes the following steps:

1. Automatic capping and capping: Bottle caps are automatically organized and transferred to the capping station by capping machine or loading machine. The bottles are fed into the capping station by conveyor belt or turntable, and keep stable position.

2. Automatic capping and tightening: the equipment uses servo motor or robot to tighten the caps precisely. The torque is controllable to ensure that the caps are tightened consistently without loosening or leaking.

3. Detection and rejection: Equipped with visual inspection and torque detection system, real-time detection of capping strength and sealing. The loose cap, leakage cap or crooked cap products are automatically rejected to ensure the qualification rate.

4. Automatic counting and discharging: qualified bottles are automatically counted and transferred to the next process to improve production efficiency.

Second, the core advantages of automatic capping machine

1. Improve production efficiency, reduce labor costs: automatic capping machine can realize high-speed continuous operation, production capacity of up to 2,000 bottles / hour, far more than the efficiency of manual operation. Support 24 hours uninterrupted production, significantly improve packaging efficiency. Reduce the dependence on manual operation and save labor cost.

2. Ensure capping precision and consistency: servo motor or pneumatic drive is adopted to ensure consistent capping torque for each bottle. The torque can be adjusted to avoid leakage or damage caused by too tight or too loose. The precision can be controlled to ensure the stability and sealing of the product packaging.

3. Intelligent detection and rejection function: Equipped with visual detection and torque feedback system, it automatically recognizes whether the capping strength is up to standard. Defective products are automatically rejected to ensure that 100% of the products are qualified. Real-time data recording, convenient for quality traceability and management.

4. Compatible with multi-specification bottles and caps: the equipment is suitable for multi-specification bottles and caps, which can be adjusted by changing the jigs and fixtures. Can screw cap plastic bottles, glass bottles, metal bottles and other materials containers. High flexibility, adapt to different production needs.

5. Energy saving and environmental protection, reduce loss: automated operation reduces the loss of caps and bottles. Reduce the error loss caused by manual operation, reduce production cost. Low energy consumption, help save energy and reduce carbon emissions.

Third, the application areas of automatic capping machine

1. Food and beverage industry: automatic capping machine is widely used in mineral water, fruit juice, milk, spices and other bottled food sealing capping. Ensure the sealing of capping, prevent leakage and pollution. Improve production efficiency and packaging quality to meet the needs of mass production.

2. Pharmaceutical and health care industry: In the pharmaceutical field, automatic capping machine is used for capping oral solution, syrup, eye drops and other liquid medicines. Ensure the sealing of the cap to prevent the medicine from leaking or contamination. Meet the GMP standards to ensure the safety and compliance of drug production.

3. Daily chemical and cosmetic industry: widely used in shampoo, shower gel, skin care products, disinfectant and other daily chemical products capping. Suitable for all kinds of shaped bottles and special caps, such as press caps and anti-theft caps. Improve the efficiency of capping, ensure the beauty and sealing of packaging.

4. Chemical and lubricating oil industry: used for automatic capping of motor oil, lubricating oil, antifreeze and other liquid chemical products. Prevent liquid leakage, ensure transportation and storage safety. The capping torque is precisely controllable to ensure a firm seal.

Fourth, the future development trend of automatic capping machine

1. Intelligent and data traceability: the future of automatic capping machine will be integrated with MES, ERP system to achieve data traceability and remote monitoring. Realize real-time monitoring of equipment operating status and fault prediction. Packaging data is automatically recorded to facilitate quality management and traceability.

2.AI visual inspection and defect identification: adopting AI visual inspection technology to automatically identify capping defects, such as loose cap, crooked cap or leakage cap.AI algorithm automatically corrects the capping torque to ensure the consistency of quality. Improve detection accuracy and automation level.

3. High-speed and flexible production: automatic capping machine will be further developed to high-speed and flexible, to meet the needs of multi-species small batch production. Realize automatic type change and parameter adjustment, improve equipment flexibility. To meet the different specifications of the bottle cap fast switching and efficient production.

4. Environmental protection and energy-saving design: the new automatic capping machine will adopt low energy consumption drive and high-efficiency motor to reduce energy consumption. Optimize the structure design to reduce material loss and energy consumption. Comply with green manufacturing and environmental standards.

As an important equipment in modern packaging automation production, automatic capping machine has been widely used in food and beverage, pharmaceutical, daily chemical and chemical industries with the advantages of high efficiency, precision and stability. It can significantly improve production efficiency, ensure sealing quality and consistency, while reducing labor costs and material waste. With the continuous development of intelligent, flexible and high-speed technology, automatic capping machine will play a more important role in future production, to provide enterprises with more efficient and reliable automated packaging solutions.