Release Date:2024-09-18 11:51:52 Popularity:

With the arrival of the industry 4.0 era, the fully automated intelligent production line has gradually become one of the core technologies of the manufacturing industry. This highly automated and intelligent production line deeply integrates mechanical equipment, information system, sensor technology, etc., realizing the full automation, precision and intelligence of the production process. It can not only improve production efficiency, reduce costs, but also enhance the consistency of product quality, thus providing enterprises with great advantages in the fierce market competition.

First, the concept and characteristics of fully automatic intelligent production line

Fully automatic intelligent production line refers to the automated operation of the production process through the application of robots, automation equipment, intelligent control systems and information technology. Its core is the use of intelligent equipment for production scheduling, quality testing and data feedback, reducing manual intervention, and improving production efficiency and product quality.

1. Highly automated: The fully automated intelligent production line replaces manual operation with robots and robotic arms to complete the whole process from raw material transportation to finished product packaging. The operator only needs to set the parameters on the system interface, and the production equipment can run automatically, avoiding the frequent manual operation in the traditional production line and significantly reducing labor costs.

2. Intelligent control and monitoring: Through advanced sensors and data acquisition technology, the production line monitors the running status of the equipment in real time to ensure that the equipment works under the best working conditions. The data generated in the production process will be collected and analyzed in real time, and the system automatically adjusts the equipment according to these data to optimize the production process and improve efficiency.

3. Flexible production: The fully automatic intelligent production line is highly flexible and can be quickly adjusted according to different production tasks. For example, by replacing production modules and programs, the production line can easily adapt to the production needs of different models of products, reducing the complexity of production due to product diversification.

4. Quality consistency and traceability: Intelligent production line detects various parameters of products in real time through sensors and automatic inspection equipment to ensure that each product meets the quality standards. At the same time, each production link in the production line can be traced, which helps to quickly locate and solve problems when quality issues arise, and improve product quality consistency.

Second, the composition of fully automatic intelligent production line

The successful operation of fully automated intelligent production line relies on the collaborative work of multiple systems and equipment, mainly including the following parts:

1. Automation equipment: these equipments are the basis of the production line, covering robotic arms, automatic conveyors, CNC machine tools and so on. They can complete the material handling, processing, assembly, testing and other tasks to ensure that the entire production process is carried out efficiently.

2. Intelligent control system: The core of the intelligent production line is the control system, which is managed through programming logic control (PLC), distributed control system (DCS) or industrial control computer (IPC). The control system is responsible for the automated scheduling of equipment, operation status monitoring and production process optimization and regulation to ensure that the entire production process is efficient and stable.

3. Sensor network and data acquisition system: Various types of sensors are arranged in each key node of the production line to collect the temperature, pressure, speed, position and other parameters of the equipment in real time. These data are transmitted to the central control system through the network for the system to analyze and make decisions.

4. Artificial Intelligence and Big Data Analysis: The intelligent production line analyzes the collected production data through big data technology and artificial intelligence algorithms, optimizes the production process, predicts equipment failures, and carries out automatic maintenance and adjustment. Machine learning technology can help the system continuously improve based on historical data to increase production efficiency and product quality.

5. Internet of Things (IoT) technology: IoT technology connects all devices, sensors, and information systems together, realizing real-time communication and coordination between devices and improving the synergy and efficiency of the entire production line. IoT also makes remote monitoring and maintenance possible, greatly reducing downtime caused by equipment failure.

Third, the application of automatic intelligent production line

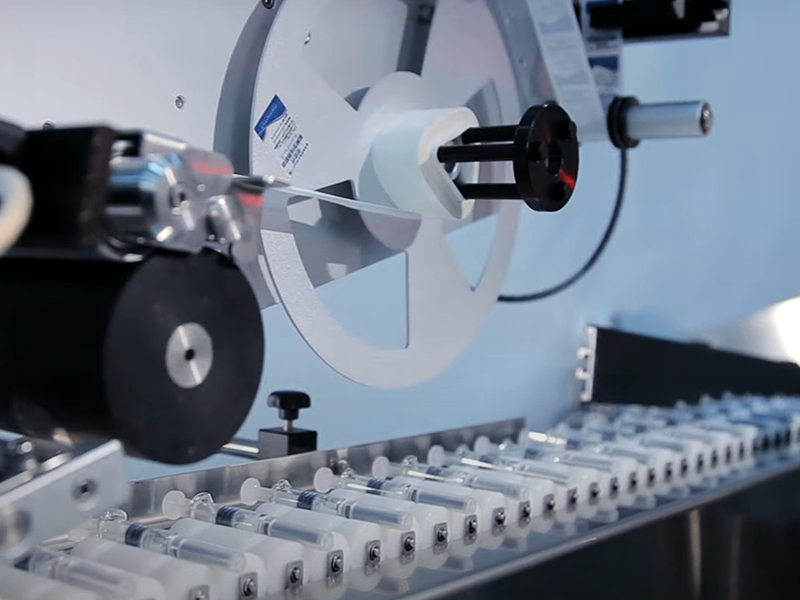

Fully automatic intelligent production line is suitable for almost all the production industries that need automation, and its application is not only limited to the manufacturing industry, but also widely used in other industries, such as food processing, pharmaceutical manufacturing, assembly of electronic products and so on. The following are some of the main application scenarios:

1. Automobile manufacturing: Automobile manufacturing is one of the most mature application areas of intelligent production line. Automated equipment and robots can complete the welding, painting, assembly and other processes of automotive parts to ensure the accuracy of each link and improve production efficiency.

2. Electronic product manufacturing: in the field of electronic product manufacturing, fully automatic intelligent production line can be used for assembling, testing and packaging of cell phones, computers and other products. As the production of electronic products requires high precision, the intelligent production line ensures that each product meets the quality standards through high-precision machinery and automated testing equipment.

3. Pharmaceutical and food industry: The production process of pharmaceutical and food industry requires strict hygiene and safety standards. Intelligent production line can realize aseptic operation, precise measurement, automatic encapsulation, etc., to ensure that the products meet the hygiene standards, and at the same time, improve the production efficiency.

4. Chemical and new energy: some high-risk or complex production processes in the chemical industry can be unmanned through intelligent production lines, reducing manual intervention and improving production safety. In the field of new energy, intelligent production line is used in the production and assembly of batteries to ensure the stability of product quality and production efficiency.

Fourth, the advantages and challenges of automatic intelligent production line

The emergence of fully automatic intelligent production line brings numerous advantages to enterprises:

1. Improve production efficiency: intelligent equipment and systems can automatically adjust the production parameters, minimize human intervention in production, and greatly enhance the production speed.

2. Reduce costs: The fully automated production process reduces the need for labor and lowers labor costs. At the same time, the precise control of the intelligent production line reduces material waste, further reducing production costs.

3. Enhance product quality: automatic inspection and real-time data monitoring ensure product quality consistency and traceability, greatly reducing the generation of defective products.

However, fully automated intelligent production line also faces some challenges in the promotion:

1. High initial investment: the construction cost of fully automated intelligent production line is high, especially small enterprises may not be able to afford the huge initial investment.

2. Shortage of technical personnel: the operation and maintenance of the intelligent production line requires professional skills of technical personnel, the current market shortage of such talent, affecting the promotion and application of equipment.

Fully automated intelligent production line represents the future development direction of industrial automation and intelligence, which has brought significant production benefits and quality improvement for various industries. With the further maturation of the technology, more enterprises will adopt this advanced production mode in the future, promoting the global manufacturing industry to a more intelligent and efficient direction.