Release Date:2024-09-12 11:47:23 Popularity:

With the advent of the Industry 4.0 era, the application of automation technology is booming in the global manufacturing industry, especially in the field of assembly. Automatic assembly equipment, as the core equipment for realizing modern production intelligence and efficiency, has become an indispensable part of the production process in various industries. Through mechanized operation, intelligent control systems and sensor technology, such equipment automatically assembles parts into products, which significantly improves production efficiency and product quality, and at the same time reduces production costs. In this paper, we will discuss in depth the principle of automatic assembly equipment, advantages and its impact on the manufacturing industry.

First, the definition and working principle of automatic assembly equipment

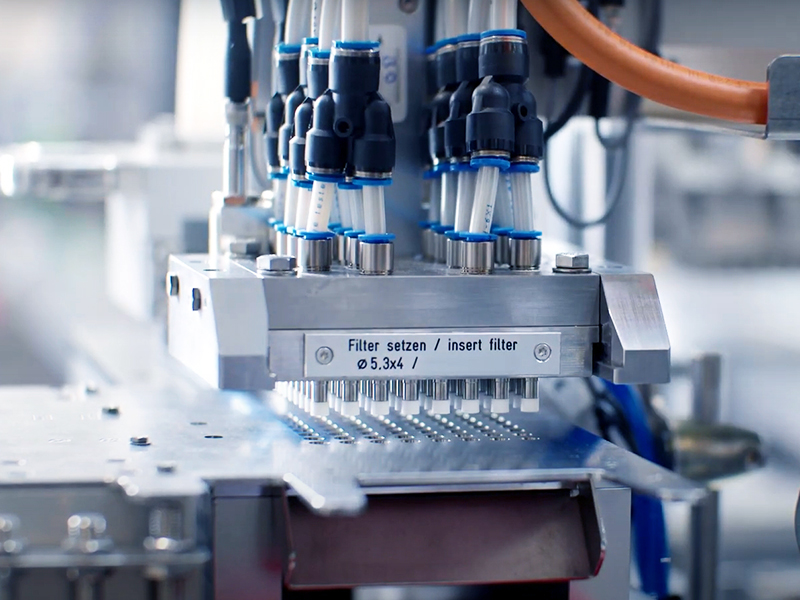

Automatic assembly equipment is a machine or system that can automatically perform the product assembly process, usually used for multiple parts in accordance with the established procedures and process order to assemble a complete product. The operation of the equipment is completely controlled by the program, mainly including parts supply, positioning, assembly, fastening, testing and other processes. Its core technology includes robotic arms, sensors, PLC control systems and precision machining equipment.

The working principle of automatic assembly equipment is usually divided into the following steps:

1. Parts supply and positioning: the equipment supplies the parts to be assembled to the specified position through the automatic loading system, and the sensor detects whether the position of the parts is correct. This process ensures that each part is accurately transferred to the next assembly station.

2. Assembly and operation: Robotic arms or other automatic assembly tools accurately assemble, connect or fasten the parts according to a preset program. This part usually adopts high-precision assembly mechanism to ensure the assembly quality of each part.

3. Quality Inspection and Adjustment: After the assembly is completed, the equipment will inspect the products, such as the size, connection solidity and other parameters, if abnormalities are found, the equipment will automatically adjust or reject the substandard products.

4. Finished product output and packaging: the assembled products are output to the next process through conveyor belt or other means, such as testing or packaging.

Second, the advantages of automatic assembly equipment

1. Improve production efficiency: one of the main advantages of automatic assembly equipment is that it can significantly improve production efficiency. The traditional manual assembly process requires a lot of manpower and time, while the automatic assembly equipment can realize 24-hour uninterrupted operation, greatly reducing the production cycle of the product. For products that require a large number of repetitive operations, automatic assembly equipment can complete a large number of products in a short period of time.

2. Reduce production costs: the use of automatic assembly equipment can effectively reduce the dependence on labor, thereby significantly reducing labor costs. As labor prices continue to rise, the application of automated equipment can help companies save a lot of money in long-term operations. In addition, automatic assembly equipment can also reduce the waste of materials caused by manual errors and improve the utilization of raw materials.

3. Improve product quality and consistency: automatic assembly equipment through precise mechanical operation, to ensure that the assembly process of each product meets the uniform standards, thus ensuring the consistency of product quality. Compared with manual operation, the machine can maintain higher precision and consistency when performing complex assembly operations, avoiding possible deviations in human operation.

4. Enhance safety: In some dangerous or unsuitable for manual operation of the production environment, such as high temperature, high pressure or hazardous chemicals environment, automatic assembly equipment can replace the workers to complete the operation, reduce the exposure time of the workers in the hazardous environment, thereby enhancing the safety of production.

5. Flexibility and scalability: modern automatic assembly equipment has a high degree of flexibility, can be adjusted through simple programming to adapt to the production needs of different products. This means that companies can produce different types of products through software upgrades or simple hardware modifications without having to replace the entire production line, thus increasing the utilization rate and flexibility of the production line.

Third, the application of automatic assembly equipment in various industries

The wide application of automatic assembly equipment has been involved in many industries, covering automobile manufacturing, electronic products, household appliances, medical equipment, toys and other fields. Specific applications include:

1. Automobile manufacturing: In the process of automobile manufacturing, automatic assembly equipment is mainly used for the automatic assembly of parts and components, such as engines, transmissions, doors and instrument panels. Through automatic assembly, not only can the assembly precision be improved, but also can reduce manual intervention and improve the efficiency and consistency of the production line.

2. Electronic product manufacturing: electronic products usually have precise and complex structure, especially cell phones, computers and other small electronic equipment assembly requires very high precision and operating speed. Automatic assembly equipment in these areas to play a big role in helping enterprises to realize high-precision automated production.

3. Household appliances and medical equipment: Household appliances such as washing machines, television sets, assembly processes, relying on automation equipment to speed up the assembly speed, to ensure the stability and efficiency of production. The production of medical devices requires the intervention of automation equipment to ensure that each product meets the strict health standards and quality requirements in the production process.

Fourth, the future development trend of automatic assembly equipment

With the rapid development of science and technology, automatic assembly equipment in the future will be more intelligent, flexible and green direction. Specific trends include:

1. The combination of artificial intelligence and big data: the future of automatic assembly equipment will be through artificial intelligence technology for independent learning and optimization, able to automatically adjust the assembly process according to the production data to further improve efficiency and quality. At the same time, through the analysis of big data, enterprises can monitor the operation of the production line in real time and predict equipment failure in advance.

2. New mode of human-machine collaboration: In the future, the mode of human-machine collaboration will be more popular, workers and machines will work together to complete more complex assembly tasks. Robots can perform heavy repetitive tasks, while workers can be involved in equipment maintenance, supervision and difficult operations.

3. Green manufacturing and environmental protection: green manufacturing will become one of the important trends in automatic assembly equipment. Future equipment design will pay more attention to energy saving and emission reduction, reduce resource consumption and promote sustainable development.

Automatic assembly equipment, as an important part of modern industry, is constantly pushing the manufacturing industry in the direction of more efficient and intelligent development. Through technological innovation and flexible application, automatic assembly equipment will provide more competitive production solutions for various industries. In the future, with the progress of science and technology, automatic assembly equipment will show its great potential in more fields.