Release Date:2024-08-29 15:36:25 Popularity:

In the rapid development of the global manufacturing industry today, production efficiency and product quality has become the key to enterprises in the competitive market. Fully automatic packaging line, as a modernized equipment integrated with advanced technology and efficient management mode, has become an indispensable and important part of all kinds of manufacturing enterprises. It not only significantly improves the production efficiency, but also greatly improves the quality and consistency of product packaging. In this paper, we will discuss in detail the working principle of automatic packaging production line, the advantages and the important role in the modern manufacturing industry.

First, the working principle of automatic packaging line

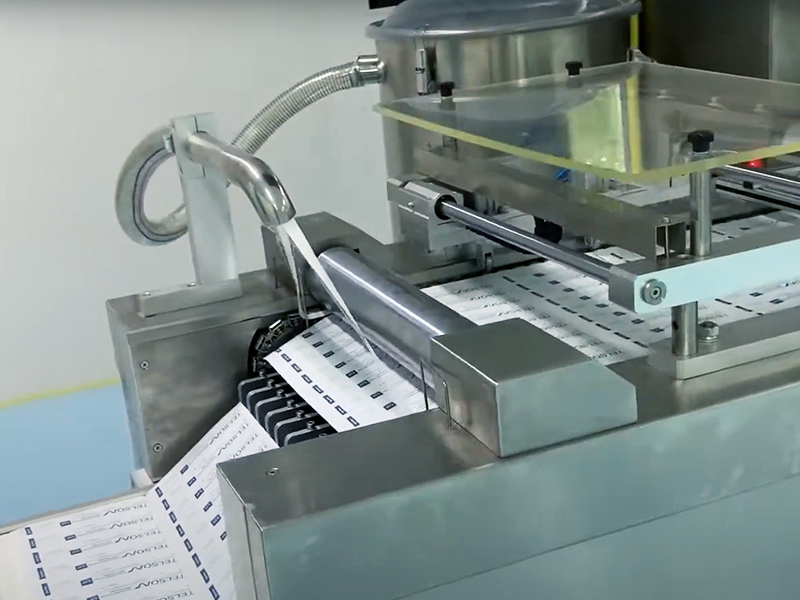

Fully automatic packaging line is a kind of automated equipment through the production of various links connected to the system. It mainly includes product delivery, quantitative filling, sealing and packaging, labeling and coding, detection and rejection and other functional modules. These modules through the coordinated operation of the automation control system, to realize the whole process of automation from raw material input to finished product packaging.

1. Product conveying: The automatic packaging production line firstly conveys the products to be packaged to each workstation automatically through the conveyor belt. The modernized conveying system can flexibly adjust the conveying speed and direction to meet the packaging needs of different products.

2. Quantitative filling: In the food, beverage, cosmetics and other industries, quantitative filling is a very critical part of the packaging process. Through precise sensors and control system, the automatic filling machine is able to accurately fill materials into packaging containers according to the set parameters, ensuring that each product has the same specifications.

3. Sealing and packaging: after the filling is completed, the production line will automatically seal and package. According to the characteristics of different products, the production line can choose hot sealing, cold sealing, vacuum packaging and other sealing methods to ensure that the product will not be contaminated or damaged during transportation and storage.

4. Labeling and coding: After sealing, the production line will automatically label and code the packaged products. Modern labeling machine can complete the labeling with high speed and accuracy, while the coding equipment can print the date of production, batch number and other information according to the need to improve the traceability of the product.

5. Detection and rejection: In order to ensure product quality, the automatic packaging production line is also integrated with an automatic detection system. The system is able to monitor various indicators in the packaging process in real time, such as filling volume, sealing tightness, labeling position and so on. If unqualified products are found, the inspection system will automatically reject them to prevent the unqualified products from flowing into the market.

Second, the advantages of automatic packaging production line

Fully automatic packaging production line has significant advantages over the traditional semi-automatic or manual packaging methods. These advantages make fully automatic packaging production line in the modern manufacturing industry occupies an important position.

1. Efficient production: automatic packaging line can significantly improve production efficiency. Its high-speed operation and automation drastically reduce the involvement of manual operation, thus shortening the production cycle. This high efficiency is especially obvious in mass production scenarios, and can help companies respond quickly to market demand.

2. Precise control: The fully automated packaging production line is able to accurately control all aspects of the packaging process through an advanced automation control system. This not only ensures the consistency of each product, but also reduces errors caused by manual operation, thus reducing production costs.

3. Saving labor costs: the wide application of fully automated packaging production line greatly reduces the enterprise's reliance on labor. Especially in areas with high labor costs, automated production lines can significantly reduce labor costs, while avoiding the uncertainty and safety hazards caused by manual operation.

4. Improve product quality: The fully automated packaging production line adopts advanced detection and rejection system, which can monitor the product quality in real time during the production process and ensure that only products that meet the standards enter the market. This not only enhances the market competitiveness of the product, but also strengthens consumer trust in the brand.

5. Strong adaptability: modern automatic packaging production line has strong adaptability and flexibility. It can quickly adapt to the packaging needs of different products through modularized design and software control system. Whether it is to replace packaging materials, adjust packaging specifications, or add new functional modules, automatic packaging production line are able to respond flexibly.

Third, the application of automatic packaging production line in the modern manufacturing industry

Fully-automatic packaging line is widely used in many industries, covering food, beverage, cosmetic, pharmaceutical, chemical and other fields. Its flexibility and high efficiency enable it to adapt to a variety of production environments and product requirements.

1. Food and beverage industry: In the food and beverage industry, fully automatic packaging lines can handle various shapes and types of packages, such as bottles, cans, bags, etc., to ensure the packaging quality and hygiene safety of products.

2. Cosmetic industry: Cosmetic industry has high requirements on the aesthetics and consistency of packaging, automatic packaging production line can accurately control the filling volume and sealing method, to ensure that the packaging of each product meets high standards.

3. Pharmaceutical industry: the pharmaceutical industry has more stringent requirements for packaging, fully automatic packaging production line can be produced in a sterile environment to ensure the safety and effectiveness of drugs.

4. Chemical industry: the packaging of chemical industry usually involves dangerous or corrosive substances, fully automatic packaging production line through automation and intelligent design, can effectively reduce the operational risks and ensure production safety.

As the core power of modern manufacturing industry, fully automatic packaging production line is constantly promoting the improvement of production efficiency and product quality in various industries. Its high efficiency, precision and flexibility make it an important tool for enterprises to maintain their advantages in the fierce market competition. With the continuous progress of automation technology, fully automatic packaging production line will be further intelligent and modular, bringing more possibilities and innovative space for the future manufacturing industry.