Release Date:2024-08-23 14:23:23 Popularity:

With the continuous upgrading and development of global manufacturing industry, automatic assembly line becomes an indispensable and important part of modern industrial production. Automatic assembly line is the use of automation technology, the automation of various processes connected to realize the fully automatic assembly and production of products. This production mode not only improves the production efficiency, reduces the labor cost, but also ensures the consistency and stability of product quality. In this paper, we will discuss the basic principle, advantages, application areas and future development trend of automatic assembly production line.

First, the basic principle of automatic assembly line

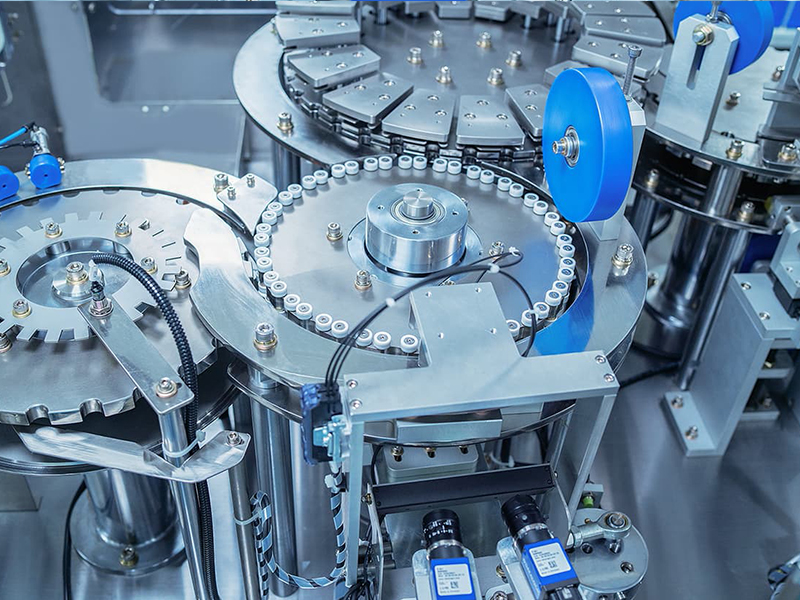

Automatic assembly line is a variety of mechanical equipment, control systems and automation technology integrated into the production system. The basic principle is that through the automation control system (such as PLC, robots, sensors, etc.) to realize the seamless integration of various production processes, so as to automatically complete the product assembly process.

The entire production line usually consists of multiple workstations, each of which performs specific operations, such as positioning, fastening, welding, and testing of parts. Sensors and vision systems are used to monitor the production process in real time to ensure that each process is completed as required. Once an abnormality is detected, the system automatically adjusts or stops the machine to avoid production accidents or defective products. Finally, the finished products are transported to the next production process or directly packed into the warehouse through the automatic conveyor belt.

Second, the advantages of automatic assembly line

1. Improve production efficiency: automatic assembly line can run 24 hours non-stop, greatly improving production efficiency. Compared with the traditional manual assembly, the automatic production line can complete the assembly of a large number of products in a short period of time, greatly reducing the production cycle.

2. Ensure product quality: The automatic assembly line can ensure the precision and consistency of each assembly link through the precise automatic control system. The high-precision operation avoids quality problems caused by human factors and improves the qualified rate of products.

3. Reduce production cost: the automatic production line reduces the dependence on human labor, thus reducing labor cost. In addition, the efficient operation and automatic inspection function of the production line can effectively reduce the material waste and defective product rate, thus further reducing the production cost.

4. Enhance enterprise competitiveness: By introducing automatic assembly lines, enterprises can not only improve the market competitiveness of their products, but also accelerate the time-to-market of their products. This is a significant advantage in the rapidly changing market environment, which helps enterprises seize the market opportunities.

5. Adapt to diversified production needs: the modern market demand for products is increasingly diversified, the flexibility of the automatic assembly line allows enterprises to quickly adjust the production line to adapt to the production needs of different products. Through programming adjustments, the production line can achieve rapid switching of different products to meet the individual needs of customers.

Third, the application field of automatic assembly line

Automatic assembly line is widely used in various manufacturing industries, especially in the following areas are particularly prominent:

1. Electronic manufacturing industry: In the electronic manufacturing industry, automatic assembly lines are widely used in the assembly of cell phones, computers, household appliances and other products. These products are usually composed of multiple precision parts, automatic assembly line can ensure the precise installation of each part, to ensure the high quality of the product.

2. Automobile manufacturing industry: the automobile manufacturing process is complex, involving the assembly of a large number of parts. The automatic assembly line can realize the automatic assembly of engine, transmission, body and other key parts, ensure the accuracy and consistency of assembly, and greatly improve production efficiency.

3. Medical device industry: medical devices require extremely high product quality, automatic assembly line has significant advantages in ensuring product quality. Automated production line in aseptic environment can effectively reduce human contact and ensure product safety and reliability.

4. Household goods industry: the production of furniture, lamps, kitchenware and other household goods is also more and more dependent on the automatic assembly line. Through automated production, can improve production efficiency, reduce costs, and ensure product consistency and quality.

Fourth, the development trend of automatic assembly production line

1. Intelligent development: with the development of Industry 4.0 and Internet of Things (IoT) technology, the automatic assembly production line is developing in the direction of intelligence. Intelligent production line through big data analysis, artificial intelligence, machine learning and other technologies to achieve real-time monitoring and optimization of the production process, and further improve production efficiency and product quality.

2. Green manufacturing: the future automatic assembly line will pay more attention to environmental protection and sustainable development. Through the application of energy-saving technology to reduce energy consumption and waste emissions, to achieve green manufacturing. The production line will also use renewable materials to reduce the impact on the environment.

3. Collaborative manufacturing: In the context of globalization, the collaborative manufacturing mode of automatic assembly lines will be widely used. Through network technology, multiple production lines can work together in different locations, realizing worldwide production synergy and improving production efficiency and resource utilization.

4. Modularization and Flexibility: In order to adapt to the rapid changes in the market, the future automatic assembly line will be more modular and flexible. Enterprises can quickly replace or adjust the modules of the production line according to the production demand, in order to cope with the production demand of different products.

As a key driver of modern manufacturing, automatic assembly line has played an important role in various industries. It not only improves production efficiency and reduces costs, but also provides flexible production solutions for enterprises. With the continuous progress of science and technology, automatic assembly line will develop in the direction of more intelligent, green and flexible, bringing more possibilities for the future of manufacturing. Enterprises should fully consider their own production needs and market environment when introducing automatic assembly lines, and choose suitable automation solutions to maximize production benefits.