Release Date:2024-08-13 16:54:39 Popularity:

With the continuous upgrading and transformation of the global manufacturing industry, automated production line equipment has become an indispensable and important part of modern industrial production. These equipment not only improves production efficiency, but also greatly improves product quality and the stability of the production process. Through the integration and optimization of technology, automated production line equipment is leading the manufacturing industry into a new era of intelligence, efficiency and flexibility. This article will explore in depth the characteristics, advantages, application scenarios and future development trends of automated production line equipment.

1. Characteristics and composition of automated production line equipment

Automated production line equipment refers to a system that uses automation technology and equipment to achieve continuous production or processing of products during the production process. The system usually consists of the following parts:

1. Automated control system: The core of the automated production line is its control system, which is usually controlled by PLC (programmable logic controller) or industrial computer. The control system is responsible for coordinating the various equipment on the production line so that it can produce according to the set process and rhythm.

2. Material conveying system: The material conveying system is an indispensable part of the automated production line, responsible for conveying raw materials or semi-finished products between various production processes. Common conveying methods include belt conveyors, roller conveyors, chain conveyors, etc.

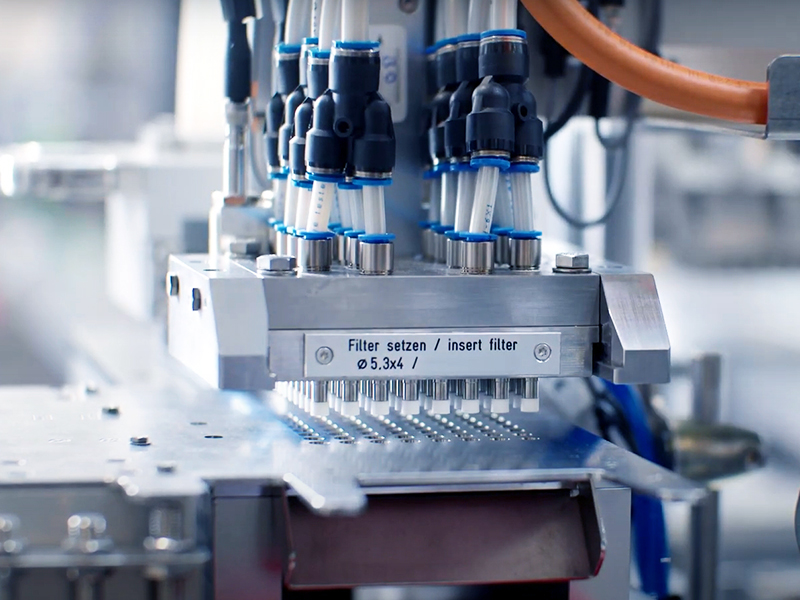

3. Processing equipment: According to the specific needs of the production line, processing equipment includes lathes, milling machines, drilling machines, welding equipment, spraying equipment, etc. These equipment automatically complete the processing, assembly or processing of products according to the process requirements of the products.

4. Testing and quality control equipment: Automated production lines are usually equipped with online testing and quality control equipment to monitor the quality of products in real time during the production process. Common testing equipment includes visual inspection systems, dimension measuring instruments, air leakage detectors, etc.

5. Automatic assembly and packaging equipment: At the end of the automated production line, automatic assembly and packaging equipment are usually equipped to complete the final assembly and packaging of the product. Robots, robotic arms and other equipment are often used in this stage to ensure the assembly and packaging accuracy of the product.

2. Advantages of automated production line equipment

1. Improve production efficiency: Automated production line equipment greatly improves production efficiency through automated control and continuous production. The equipment can run for a long time and at high speed, reducing pauses and errors in human operation, making the production process smoother.

2. Ensure product quality: Through precise processing equipment and strict online testing systems, automated production lines can ensure product consistency and stability and reduce the incidence of quality problems. The high-precision operation of automated production line equipment further improves the quality of products.

3. Reduce production costs: Although the initial investment of automated production line equipment is high, its long-term operation can significantly reduce production costs. Reducing dependence on manual labor reduces labor costs and losses caused by human errors. In addition, the high efficiency and low scrap rate of the equipment also reduce the waste of raw materials.

4. Improve safety: Automated production lines reduce the frequency of manual participation and reduce the risk of workers being injured during operation. At the same time, the safety protection measures and fault warning systems equipped with the equipment further improve the safety of the production process.

5. Adapt to diversified production needs: Modern manufacturing has an increasing demand for product diversity and customization. Automated production line equipment can quickly adapt to the production requirements of different products through flexible programming and fast switching functions, and realize a multi-variety, small-batch production mode.

3. Application scenarios of automated production line equipment

1. Automobile manufacturing industry: Automated production line equipment is widely used in the automobile manufacturing industry. From body welding and painting to engine assembly and quality inspection, automated equipment runs through all aspects of automobile production, greatly improving production efficiency and product quality.

2. Electronic product manufacturing: Electronic product manufacturing has extremely high requirements for precision and efficiency. Automated production line equipment plays an important role in circuit board assembly, chip packaging, product testing and other links, ensuring product consistency and high quality.

3. Food processing: In the food processing industry, automated production line equipment is widely used in raw material processing, product packaging, label attachment and other links, ensuring the hygiene and safety of food production and improving production efficiency.

4. Pharmaceutical production: Pharmaceutical production has extremely strict requirements on environment, hygiene and precision. Automated production line equipment ensures the safety and consistency of drug production through aseptic filling, automatic packaging, online testing and other technologies.

5. Home appliance manufacturing: Automated production line equipment is mainly used in parts assembly, whole machine assembly, functional testing and other links in the home appliance manufacturing industry, which can effectively improve product production efficiency and assembly accuracy.

4. Development trend of automated production line equipment

1. Intelligence and digitalization: In the future, automated production line equipment will further develop in the direction of intelligence and digitalization. By introducing technologies such as artificial intelligence, big data, and the Internet of Things, equipment can achieve self-monitoring, self-optimization and fault prediction, greatly improving production efficiency and equipment operation stability.

2. Flexible production: In order to adapt to the rapid changes and diversified needs of the market, flexible production lines will become an important development direction for automation equipment. Through modular design and flexible programming, the equipment can quickly adjust the configuration of the production line, realize multi-variety and small-batch production, and meet the personalized needs of different customers.

3. Green manufacturing: Against the background of increasing global environmental awareness, the development of automated production line equipment will pay more attention to energy conservation and emission reduction and environmental protection design. The energy consumption of the equipment will be further reduced, while more attention will be paid to reducing the generation of waste and pollutants, promoting the realization of green manufacturing.

4. Human-machine collaboration: Human-machine collaboration will become an important direction for automated production line equipment in the future. Through the collaborative work of intelligent robots and automated equipment, the efficiency of the equipment can be brought into play, and complex production tasks can be flexibly responded to, thus improving the efficiency of the overall production line.

In short, as the core technology of modern manufacturing, automated production line equipment is driving the industry to move forward in the direction of intelligence, efficiency, and flexibility. With the continuous advancement of technology, these devices will bring more innovation and change to the manufacturing industry, helping enterprises gain an advantage in global competition.