Release Date:2024-08-07 16:02:16 Popularity:

In today's fierce competition in the manufacturing industry, standardized production equipment can no longer meet the diversified and personalized production needs. Non-standard automated assembly equipment has become a key driving force for the upgrading of the manufacturing industry due to its high degree of customization and flexibility. This article will discuss in detail the importance, development process, application fields and future development trends of non-standard automated assembly equipment.

1. The importance of non-standard automated assembly equipment

1. Meet personalized needs: The production process and product requirements of each manufacturing enterprise are different, and standardized equipment is difficult to fully match. Non-standard automated assembly equipment can be customized according to the specific needs of the enterprise to ensure that the equipment is highly compatible with the production process.

2. Improve production efficiency: Customized equipment can optimize specific production links, reduce manual operations, and increase the degree of automation, thereby significantly improving production efficiency.

3. Enhance market competitiveness: By adopting non-standard automated assembly equipment, enterprises can achieve unique production advantages, such as higher precision, faster production speed or lower cost, and enhance market competitiveness.

4. Reduce production costs: Although the initial investment of non-standard equipment is high, by improving production efficiency, reducing labor costs and reducing defective rates, production costs can be significantly reduced in the long run.

2. Development process of non-standard automated assembly equipment

1. Demand analysis: The first step in development is to understand the customer's production needs, existing processes and problems in detail. Through in-depth communication, clarify the functions and performance requirements of the equipment.

2. Scheme design: According to the results of demand analysis, design a preliminary scheme, including the overall structure, working principle, technical parameters and operation process of the equipment. This stage usually requires repeated discussions with customers to ensure the feasibility and economy of the scheme.

3. Detailed design: After the scheme is determined, detailed design is carried out, including mechanical design, electrical design and software design. Detailed design requires comprehensive consideration of the accuracy, stability, safety and ease of operation of the equipment.

4. Manufacturing and assembly: Manufacture and assemble the equipment according to the design drawings and technical requirements. This process includes parts processing, welding, assembly and preliminary debugging to ensure that the various functions of the equipment meet the design requirements.

5. Debugging and testing: After manufacturing, the equipment is fully debugged and tested to ensure that the equipment can operate stably in actual production. The test content includes running speed, accuracy, stability and safety.

6. Customer acceptance: After the equipment is debugged, it is transported to the customer's site for installation and final debugging. The customer inspects the equipment and confirms that it meets production needs.

7. Training and after-sales service: Train customer operators to ensure that they can operate and maintain the equipment correctly. At the same time, provide comprehensive after-sales service, including equipment maintenance, maintenance and troubleshooting, to ensure long-term stable operation of the equipment.

3. Application areas of non-standard automated assembly equipment

1. Automobile manufacturing: Highly precise and reliable assembly equipment is required in the automobile manufacturing process. Non-standard automated equipment plays an important role in engine assembly, body welding, and parts assembly.

2. Electronic manufacturing: The production of electronic products requires high precision and high efficiency. Non-standard automated assembly equipment can be used for automated assembly, welding and testing of electronic components to improve production efficiency and product quality.

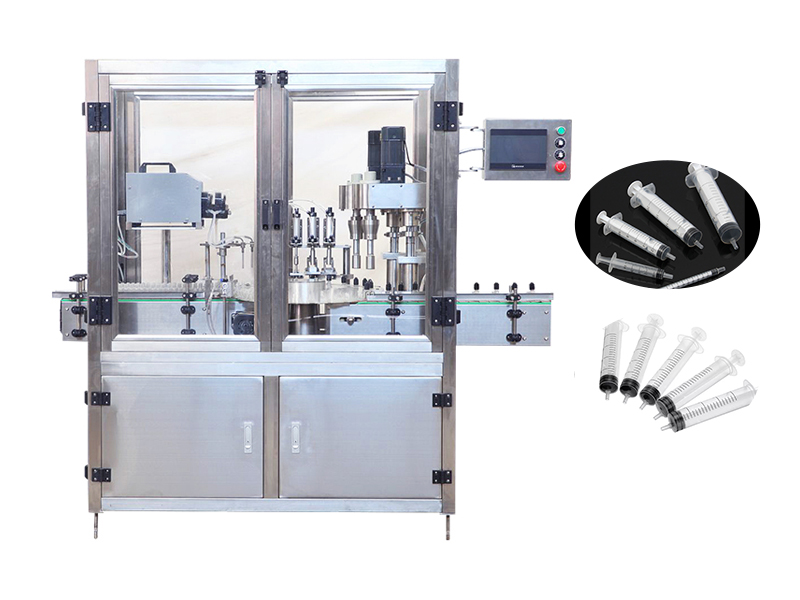

3. Medical devices: The production of medical devices has extremely high requirements for the hygiene and precision of equipment. Non-standard automated assembly equipment can be used for the automated production and assembly of medical devices to ensure the safety and reliability of products.

4. Consumer goods: In the production of consumer goods, non-standard automated assembly equipment can be used for the automated assembly of various small household appliances, toys, and household items to improve production efficiency and product consistency.

5. Aerospace: The aerospace field has extremely high requirements for the accuracy and reliability of equipment. Non-standard automated assembly equipment can meet the high-precision assembly requirements of aerospace parts and ensure product quality and safety.

4. Development trend of non-standard automated assembly equipment

1. Intelligence: With the development of artificial intelligence and Internet of Things technology, non-standard automated assembly equipment will develop in the direction of intelligence. Intelligent equipment can achieve self-monitoring, self-adjustment and self-maintenance, improving production efficiency and equipment reliability.

2. Modularity: Modular design makes non-standard equipment more flexible and easy to upgrade and maintain. Through modular design, equipment can be quickly adjusted and expanded according to demand to adapt to different production tasks.

3. Green and environmental protection: Future non-standard automated assembly equipment will pay more attention to energy conservation and environmental protection. By adopting green materials and energy-saving technologies, the energy consumption and environmental impact of equipment can be reduced to promote sustainable development.

4. Globalization: With the acceleration of the integration of global manufacturing, non-standard automated assembly equipment will be oriented to the global market. Equipment manufacturers need to understand the production needs and standards of different regions and provide customized solutions to meet the needs of global customers.

To sum up, non-standard automated assembly equipment plays a vital role in modern manufacturing. By providing highly customized solutions, non-standard automation equipment helps companies improve production efficiency, reduce costs and enhance competitiveness. In the future, with the continuous advancement of technology and changes in market demand, non-standard automated assembly equipment will continue to develop in the direction of intelligence, modularization, green environmental protection and globalization, providing a solid guarantee for the innovation and upgrading of the manufacturing industry.