Release Date:2024-08-03 14:26:21 Popularity:

Automation equipment acceptance is a crucial part of industrial production. It is not only related to the commissioning of equipment, but also directly affects production efficiency, product quality and enterprise costs. This article will discuss in detail the process, acceptance standards, key links and importance of automation equipment acceptance in modern industry.

1. Automation equipment acceptance process

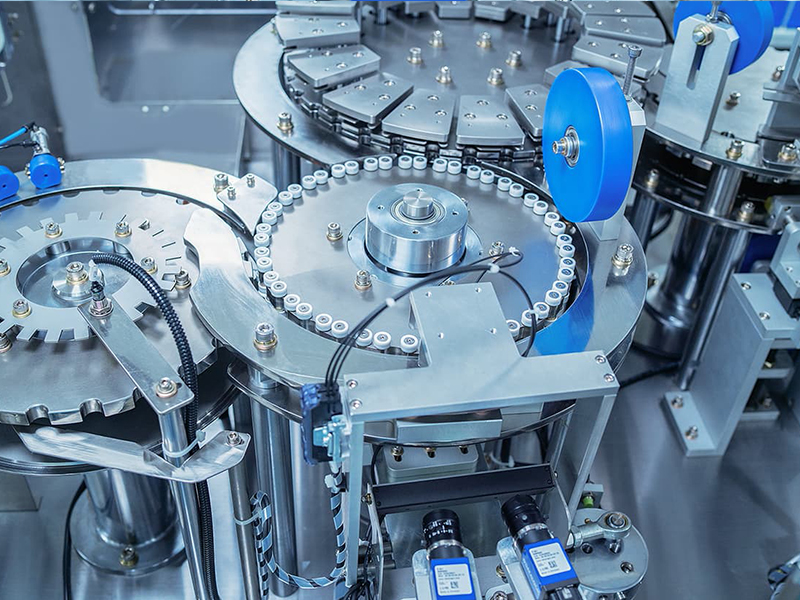

Automation equipment acceptance usually includes four main steps: equipment arrival acceptance, installation and commissioning acceptance, trial operation acceptance and final acceptance.

1. Equipment arrival acceptance: Check whether the equipment packaging is intact, and confirm whether the equipment model, specifications, quantity, etc. are consistent with the order. After the equipment arrives, check each component and accessory according to the list to check for defects and omissions.

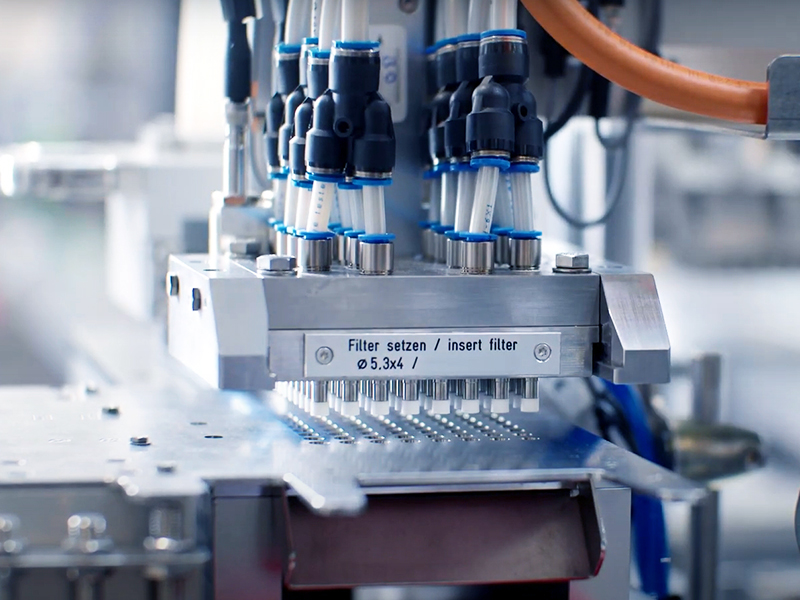

2. Installation and commissioning acceptance: Install the equipment according to the installation instructions provided by the equipment manufacturer to ensure that the equipment is installed firmly and in the correct position. After the installation is completed, conduct preliminary commissioning to check the basic functions and operating status of the equipment, such as power connection, mechanical transmission, gas connection, etc.

3. Trial operation acceptance: After the preliminary commissioning is completed, the equipment needs to be tested for a certain period of time to verify its stability and performance. During the trial run, record the equipment operating parameters and performance indicators, discover and solve potential problems, and ensure that the equipment can operate continuously and stably.

4. Final acceptance: The equipment will be subject to final acceptance after the trial run is qualified. Final acceptance includes comprehensive inspection of the equipment's technical parameters, functions, production efficiency and quality indicators. After acceptance, the equipment is officially put into production and use, and the acceptance document is signed.

2. Standards for acceptance of automation equipment

Automation equipment acceptance standards mainly include technical standards, performance standards and quality standards.

1. Technical standards: Technical standards involve equipment design specifications, manufacturing processes, material selection and other aspects. Equipment manufacturers need to provide relevant technical documents, such as design drawings, process flow, material lists, etc., for reference by acceptance personnel.

2. Performance standards: Performance standards include equipment operating speed, accuracy, stability, failure rate and other indicators. During acceptance, the equipment needs to be actually tested and various performance parameters measured to ensure that the equipment meets the design requirements and contract provisions.

3. Quality standards: Quality standards cover the appearance quality, component quality, assembly quality, etc. of the equipment. The acceptance personnel shall conduct a comprehensive inspection of the equipment to ensure that the equipment has no appearance defects, no damage to parts, and the assembly quality meets the standards.

3. Key links in the acceptance of automation equipment

1. Document review: Before acceptance, the technical documents, inspection reports, certificates of conformity, etc. provided by the equipment manufacturer shall be reviewed. Document review is an important part of equipment acceptance to ensure that the equipment meets technical specifications and quality standards.

2. On-site inspection: On-site inspection includes appearance inspection, parts inspection, installation inspection, operation inspection, etc. of the equipment. On-site inspection shall be carried out strictly in accordance with the acceptance standards to ensure that all indicators of the equipment meet the requirements.

3. Functional testing: Functional testing is a key link in verifying the performance of the equipment. By testing the equipment under different working conditions, measuring the operating parameters and performance indicators of the equipment, it is ensured that the equipment can meet production needs.

4. Problem handling: Problems found during the acceptance process shall be recorded in a timely manner and communicated with the equipment manufacturer to solve them. Problem handling includes on-site debugging, parts replacement, parameter adjustment, etc. to ensure that the equipment can operate normally.

4. Importance of Automation Equipment Acceptance

1. Ensure production efficiency: Through strict equipment acceptance, it can be ensured that the equipment can operate efficiently after being put into use, reduce downtime due to failures, and improve production efficiency.

2. Improve product quality: Equipment acceptance can ensure that the accuracy and performance of the equipment meet the requirements, thereby ensuring the stable quality of the products produced and improving the market competitiveness of the enterprise.

3. Reduce production costs: Strict equipment acceptance can reduce the frequency of maintenance and replacement of equipment during use and reduce production costs. At the same time, problems found through acceptance can be solved within the equipment warranty period to avoid additional maintenance costs.

4. Ensure safe production: Equipment acceptance can discover and eliminate potential safety hazards, ensure the safety of equipment during use, and ensure the safety of production personnel.

5. Future development trends of automation equipment acceptance

1. Intelligent acceptance: With the development of Industry 4.0, automation equipment acceptance will be more intelligent. Through intelligent sensors, data acquisition and analysis systems, real-time monitoring and analysis of equipment status can be achieved to improve the accuracy and efficiency of acceptance.

2. Remote acceptance: In the future, remote acceptance technology will be widely used. Through remote video monitoring, virtual reality (VR) technology, etc., remote acceptance and debugging of equipment can be realized, acceptance costs can be reduced, and acceptance efficiency can be improved.

3. Standardized acceptance: The acceptance of automated equipment will develop in the direction of standardization. By formulating unified acceptance standards and specifications, the scientificity and fairness of equipment acceptance can be improved, and the consistency of equipment quality and performance can be ensured.

4. Digital management: In the future, equipment acceptance will rely more on digital management. By establishing an equipment acceptance database and management system, digital storage and management of acceptance information can be realized, and the transparency and traceability of acceptance work can be improved.

In summary, automated equipment acceptance is an important link to ensure production efficiency and quality. Through strict acceptance processes and standards, the stable operation of equipment can be ensured, production efficiency can be improved, and production costs can be reduced. With the development of technology, equipment acceptance will be more intelligent, standardized and digitalized, providing more efficient and reliable guarantees for modern industry.