Release Date:2024-08-01 11:52:11 Popularity:

Filling machines play an important role in modern production lines, and their filling accuracy directly affects product quality, cost control and market competitiveness. Whether in food and beverage, pharmaceutical chemicals, or daily chemicals, the accuracy of filling machines is one of the key indicators for evaluating equipment performance. This article will discuss in detail the factors affecting the filling accuracy of filling machines, technological progress and its application in various industries.

1. Key factors affecting filling accuracy

1. Metering system: The metering system is the core component that determines the filling accuracy of the filling machine. Common metering systems include piston type, flow meter type, weight type and time control type. The piston metering system relies on mechanical movement to achieve precise control, the flow meter type measures the fluid flow rate, the weight type uses a weighing sensor, and the time control type adjusts the flow rate by time. The accuracy and stability of these systems directly affect the filling accuracy.

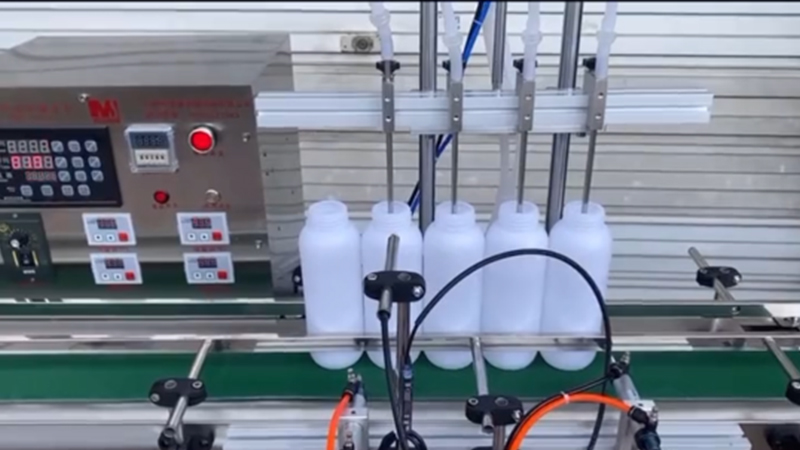

2. Filling head design: The design of the filling head has an important influence on the filling accuracy. Anti-drip design, anti-foam design and anti-blocking design can effectively avoid errors in the filling process. Each filling head of a multi-head filling machine must ensure synchronization and consistency, otherwise it will lead to uneven filling volume.

3. Liquid characteristics: The viscosity, density, temperature and fluidity of the liquid will affect the filling accuracy. High-viscosity liquids require higher pressure and longer filling time, while low-viscosity liquids are prone to splashing and foaming. Different liquid characteristics require different filling technologies and equipment adjustments.

4. Equipment stability: The mechanical stability of the equipment and the consistency of operation are the basis for ensuring filling accuracy. Wear, looseness or instability of any mechanical parts will lead to filling errors. High-quality manufacturing processes and regular maintenance are the key to ensuring equipment stability.

5. Environmental factors: External environmental factors such as ambient temperature, humidity, and air flow will also affect filling accuracy. For example, temperature changes may cause changes in liquid volume, and humidity affects the performance of electrical components. Therefore, the environment should be kept as stable as possible during the filling process.

2. Technological progress in improving filling accuracy

1. Intelligent control system: Modern filling machines generally use advanced PLC (programmable logic controller) and HMI (human-machine interface) control systems to achieve precise automatic control. By monitoring the filling process in real time through sensors, the intelligent control system can automatically adjust the filling parameters according to the actual situation and improve the filling accuracy.

2. Servo drive technology: The application of servo drive technology in filling machines makes the filling process smoother and more accurate. The servo motor can achieve precise speed and position control and reduce errors in the filling process. Especially in multi-head filling machines, servo drive technology can ensure the synchronization and consistency of each filling head.

3. High-precision sensors: The application of high-precision sensors improves the metering accuracy of the filling machine. Weight sensors, flow sensors, and pressure sensors can detect the filling volume in real time and feed the data back to the control system for precise adjustment. The accuracy and response speed of the sensor directly affect the filling accuracy.

4. Automatic calibration system: Modern filling machines are equipped with automatic calibration systems, which can adjust parameters in real time during the filling process to ensure the accuracy of the filling volume. The automatic calibration system automatically corrects errors by comparing the set value and the actual filling volume, avoiding the instability of manual adjustment.

5. Anti-foaming and anti-drip technology: Foaming and dripping often occur during liquid filling, affecting the filling accuracy. Anti-foaming technology reduces the generation of foam by optimizing the filling head design and filling method; anti-drip technology avoids liquid dripping after filling through a special filling valve design, thereby improving filling accuracy.

3. Application of filling accuracy in various industries

1. Food and beverage industry: In the food and beverage industry, filling accuracy is directly related to the taste, shelf life and cost control of the product. High-precision filling equipment can ensure the consistent capacity of each bottle of beverage, avoid overdose or underdose, thereby improving consumer satisfaction and corporate economic benefits.

2. Pharmaceutical industry: The pharmaceutical industry has strict requirements on filling accuracy, especially in the filling process of liquid medicine, reagents and vaccines. Any slight error may affect the efficacy and safety of the medicine. High-precision filling machines can ensure the accurate dosage of each liquid medicine, meeting the high standards of the pharmaceutical industry.

3. Chemical industry: The filling accuracy of chemical products is related to the effect of chemical reactions and the quality of products. Liquid filling in the chemical industry usually involves corrosive, volatile or high-viscosity liquids, which puts higher requirements on the accuracy and durability of filling machines. High-precision filling machines can ensure the quality stability and safety of chemical products.

4. Daily chemical industry: Daily chemical products such as shampoo, shower gel, detergent, etc. have high requirements for filling accuracy, especially the market's attention to product packaging consistency. High-precision filling equipment can ensure the consistent capacity of each bottle of product, improve brand image and market competitiveness.

4. Future development trends

1. Intelligence and automation: With the development of Industry 4.0, filling machines will be more intelligent and automated. The equipment will be equipped with more sensors and intelligent control systems to achieve self-diagnosis, self-adjustment and remote monitoring, and further improve filling accuracy and production efficiency.

2. Green and environmental protection: Future filling equipment will pay more attention to green and environmental protection design, reduce energy consumption and material waste. Accurate filling control can not only improve production efficiency, but also reduce the impact on the environment, in line with the requirements of sustainable development.

3. Personalized customization: Different industries and products have different requirements for filling accuracy. In the future, filling machines will provide more personalized customization services. Equipment manufacturers will design and manufacture high-precision filling equipment that meets specific requirements according to customer needs to meet the diverse needs of the market.

In summary, filling accuracy is an important indicator of filling machine performance, which directly affects product quality and production efficiency. With the continuous advancement of technology, the accuracy of filling machines will be further improved, providing more reliable and efficient production solutions for various industries. In the future, intelligence, green environmental protection and personalized customization will become the main trends in the development of filling machines, promoting the continuous progress and innovation of the industry.