Release Date:2024-07-19 16:17:01 Popularity:

In the era of Industry 4.0, intelligent manufacturing has become the core of modern industry, and fully automatic assembly production lines, as an important part of it, are playing an increasingly important role. This advanced production method not only greatly improves production efficiency and product quality, but also shows significant advantages in saving costs, ensuring safety, and achieving flexible production. This article will explore the definition, working principle, advantages and application of fully automatic assembly lines in various industries.

1. Definition and working principle of fully automatic assembly production line

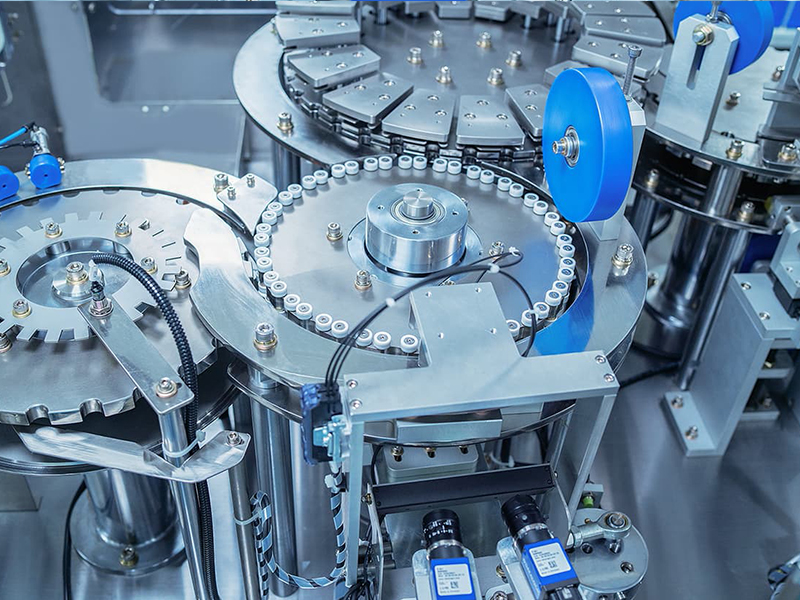

A fully automatic assembly production line refers to a production line that uses automated equipment and systems to automate all or most operations in the product assembly process. Through high-tech means such as robots, sensors, control systems and computers, the production line can automatically complete product assembly, testing, packaging and other processes.

Its working principle mainly includes the following steps:

1. Parts feeding: Raw materials and parts are transported to designated locations through the automatic feeding system, ready for assembly.

2. Assembly operation: Robots or other automated equipment assemble products according to preset procedures, including parts grabbing, positioning, installation and other operations.

3. Detection and adjustment: During the assembly process, sensors and detection equipment monitor the quality of each process in real time, and make timely adjustments and corrections if problems are found.

4. Finished product output: The assembled products are sent to packaging or the next process through conveyor belts or other conveying equipment. The entire process does not require manual intervention.

5. Data recording and analysis: The system automatically records the assembly data of each product and analyzes it for production optimization and quality traceability.

2. Advantages of fully automatic assembly production lines

1. Improve production efficiency: The fully automatic assembly production line can achieve 24-hour uninterrupted production and greatly improve production efficiency. Compared with traditional manual assembly, automated equipment is faster and the production cycle is shorter.

2. Ensure product quality: Through precise control systems and testing equipment, the fully automatic assembly production line ensures the consistent assembly quality of each product and reduces quality differences caused by human operations.

3. Reduce labor costs: Automated equipment replaces a large number of manual operations, reducing the demand for manpower and significantly reducing labor costs. At the same time, the labor intensity of workers is reduced and the working environment is improved.

4. Improve safety: Automated production lines reduce manual intervention and reduce the risk of work-related injuries. The safety protection measures and emergency stop devices of the equipment ensure the safety of the production process.

5. Achieve flexible production: The fully automatic assembly production line can flexibly adjust the production rhythm and processes according to production needs, quickly respond to market demand, and achieve multi-variety and small-batch production.

6. Data-driven optimization: Through real-time collection and analysis of production data, the production line can be continuously optimized to improve production efficiency and product quality, while providing a scientific basis for corporate decision-making.

3. Application fields of fully automatic assembly production lines

Fully automatic assembly production lines are widely used in various industries, especially in the fields of electronics, automobiles, home appliances and medical equipment.

1. Electronics industry: In electronic product manufacturing, fully automatic assembly production lines are used for the precision assembly of electronic equipment such as mobile phones and computers. High-precision equipment and strict quality control ensure the consistency and reliability of electronic products.

2. Automobile industry: In the automobile manufacturing process, fully automatic production lines are widely used for the assembly of key components such as engines and gearboxes, which not only improves production efficiency, but also improves product performance and safety.

3. Home appliance industry: Fully automatic assembly production lines are used in the production of home appliances to assemble refrigerators, washing machines and other products to ensure the high quality and stability of the products.

4. Medical device industry: Medical devices have extremely high requirements for production accuracy and hygiene. The fully automatic assembly production line operates in a sterile environment to ensure the safety and reliability of medical products.

4. Development Trend of Fully Automatic Assembly Production Lines

With the continuous advancement of science and technology, fully automatic assembly production lines are developing in the direction of intelligence, greenness and multi-function.

1. Intelligentization: In the future, fully automatic assembly production lines will make greater use of artificial intelligence, Internet of Things, big data and other technologies to achieve intelligent monitoring and management of the production process. Through machine learning and data analysis, the production process will be optimized and production efficiency improved. and quality.

2. Greening: The enhancement of environmental awareness promotes the green development of fully automatic assembly production lines, using energy-saving equipment and processes to reduce energy consumption and waste emissions, and promote sustainable production.

3. Multifunctionality: The fully automatic assembly production line will have more functions, such as automatic line changing, automatic cleaning, automatic detection, etc., to meet the diverse needs of different products and markets.

5. Implementation cases of fully automatic assembly production lines

1. An electronics manufacturing company: After an electronics manufacturing company introduced a fully automatic assembly production line, its production efficiency increased by 30%, and its product qualification rate reached over 99%, significantly improving its market competitiveness.

2. An automobile manufacturing company: An automobile manufacturing company successfully achieved efficient assembly of engines through a fully automatic assembly line, shortening the production cycle by 20%, and significantly improving product quality and performance.

To sum up, as an important production tool in the Industry 4.0 era, the fully automatic assembly line is promoting the production of various industries to become intelligent, automated and green with its advantages of high efficiency, high quality, safety and flexibility. In the future, with the continuous innovation and application of technology, fully automatic assembly lines will bring more opportunities and challenges to industrial production, pushing the global industry into a new era of more intelligent, efficient and sustainable development.