Release Date:2024-07-04 15:05:11 Popularity:

With the continuous advancement of science and technology and the increasingly fierce market competition, the position of automated production line solutions in modern manufacturing is becoming increasingly important. It not only improves production efficiency and product quality, but also reduces production costs, winning more advantages for enterprises in market competition. This article will explore the main features, implementation steps, application advantages and far-reaching impact of automated production line solutions on the manufacturing industry.

Main features of automated production line solutions

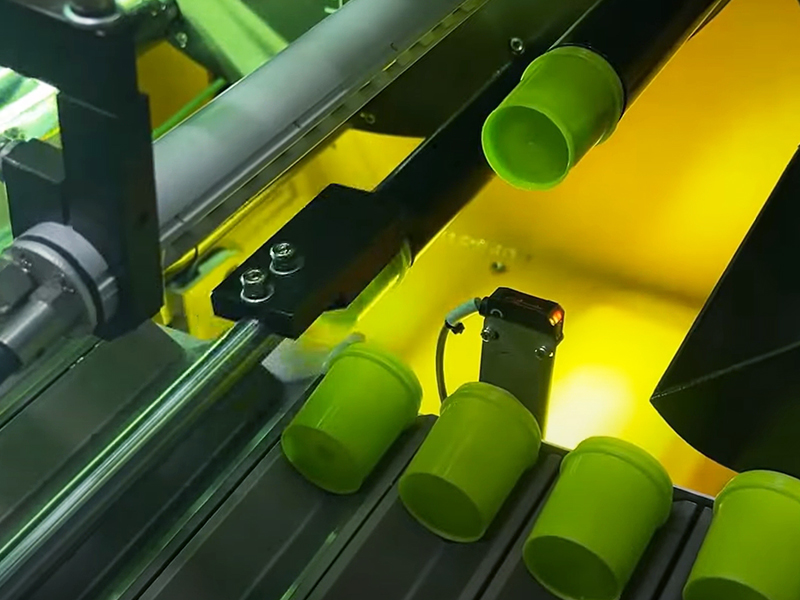

1. Efficiency: Automated production lines can complete a large number of production tasks in a short time by adopting advanced mechanical equipment and automatic control systems. The efficient production process reduces the production cycle of products and improves the market response speed of enterprises.

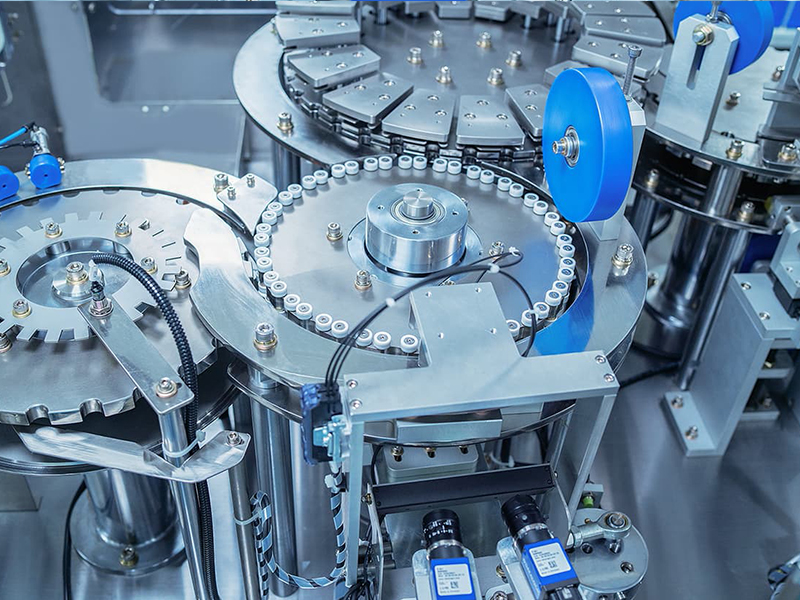

2. Accuracy: Automated equipment can operate accurately according to preset parameters to ensure the accuracy of each production link. Accurate operation reduces the scrap rate of products and improves the consistency and quality of products.

3. Stability: Automated production lines have high stability and reliability. The equipment is less affected by external factors during operation, can maintain a stable working state for a long time, and reduces fluctuations and failures in production.

4. Intelligence: Modern automated production lines integrate intelligent control systems, and realize real-time monitoring and optimization of production processes through technologies such as sensors, data analysis and machine learning. Intelligent systems can automatically adjust according to production needs to improve production efficiency and quality.

5. Flexibility: Automated production lines have high flexibility and can quickly adjust and switch according to the production needs of different products. Through modular design and programmable control, production lines can adapt to a variety of production tasks.

Implementation steps of automated production line solutions

1. Demand analysis: First, it is necessary to conduct a detailed analysis of the company's production needs and clarify the goals and requirements of the production line. This includes production scale, product types, production cycle, quality requirements, etc.

2. Solution design: According to the results of demand analysis, formulate specific automated production line solutions. This includes the overall layout of the production line, equipment selection, control system design, etc.

3. Equipment selection: According to the design plan, purchase suitable automation equipment, including robots, conveyor belts, automatic assembly machines, testing equipment, etc. When purchasing equipment, its performance, quality and adaptability should be considered.

4. System integration: Integrate various automation equipment into the production line to ensure coordination and linkage between equipment. System integration needs to consider the connection method, communication protocol, data interface, etc. of the equipment.

5. Debugging and operation: Before the production line is put into formal operation, comprehensive debugging and testing are required to ensure the normal operation of all links of the production line. During the debugging process, the operating status, production efficiency, product quality, etc. of the equipment should be tested.

6. Training and maintenance: Train the operators of the production line to ensure that they master the operation methods and maintenance skills of the equipment. At the same time, formulate a detailed maintenance plan to ensure the long-term stable operation of the production line.

Application advantages of automated production line solutions

1. Improve production efficiency: The automated production line solution significantly improves production efficiency through the efficient operation of automated equipment. Automated operation not only speeds up production, but also reduces errors and time waste in manual operation, and improves the overall efficiency of the production line.

2. Improve product quality: High-precision automated equipment and intelligent control systems ensure the accuracy and consistency of the production process. Automated production lines reduce quality fluctuations caused by manual operation, and improve product consistency and market competitiveness.

3. Reduce production costs: Although the initial investment of automated production lines is high, its efficient production capacity and low operating costs significantly reduce the overall production costs. Automated equipment reduces dependence on manual labor, and reduces labor costs and management costs. At the same time, the precise control system reduces the waste of raw materials and energy and improves resource utilization.

4. Improve production safety: By replacing manual work to complete some dangerous tasks, the automated production line reduces the chances of workers being exposed to harmful substances and dangerous environments, and improves the safety of the production process. The intelligent system can also monitor the production status in real time, and promptly discover and deal with potential safety hazards.

5. Enhance market competitiveness: The automated production line can quickly adjust production according to market demand, which improves the market response speed of the enterprise. Efficient production capacity and high-quality product quality enable enterprises to occupy a favorable position in the fierce market competition.

The automated production line solution is leading the manufacturing industry towards intelligence and efficiency with its high efficiency, precision, stability, intelligence and flexibility. It has significant advantages in improving production efficiency, improving product quality, reducing production costs and enhancing market competitiveness, and has become an important means for modern manufacturing companies to enhance their competitiveness. With the continuous advancement of science and technology, the automated production line solution will continue to develop and bring more innovations and opportunities to the manufacturing industry. In the future, the automated production line solution will continue to play its important role and promote the manufacturing industry to move towards a more efficient, intelligent and sustainable development direction.