Release Date:2024-06-29 11:03:40 Popularity:

In the food processing industry, sauce, as an important condiment, is widely used and in high demand. In order to meet market demand and improve production efficiency, more and more food companies are beginning to adopt fully automatic sauce packaging machines. This advanced packaging equipment not only improves production efficiency, but also significantly improves product quality and safety. This article will discuss in detail the working principle, main features, application areas and advantages of the fully automatic sauce packaging machine in sauce production.

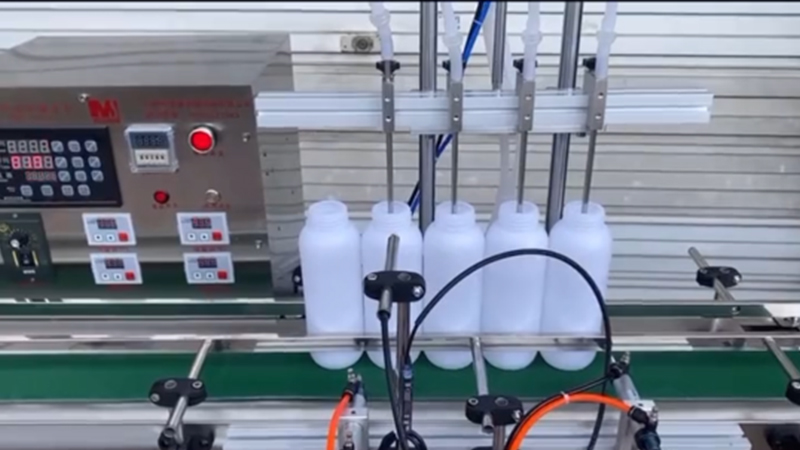

The core principle of the fully automatic sauce packaging machine is to achieve precise quantitative filling and packaging of sauces through automation technology. Its working process includes the following steps:

1. Feeding system: The sauce is transported from the storage tank to the filling box of the filling machine through the feeding pump to ensure stable feeding during the filling process.

2. Bottle positioning: The conveyor belt transports empty bottles or containers to the filling position, and the automatic positioning system accurately positions the bottle under the filling head.

3. Quantitative filling: The filling head accurately injects the sauce into the bottle according to the preset filling volume. The filling process is usually controlled by a servo system or a pneumatic system to ensure the accuracy and stability of the filling volume.

4. Sealing and labeling: After filling is completed, the bottle automatically enters the sealing and labeling process to ensure product sealing and labeling accuracy.

5. Inspection and packaging: After filling, sealing and labeling, the products enter the inspection area for quality inspection. Qualified products then enter the packaging process to complete the entire production process.

The main features of the fully automatic sauce packaging machine

1. Efficiency: Fully automated operation greatly improves packaging efficiency and is suitable for mass production needs. Compared with traditional manual packaging, the fully automatic sauce packaging machine can complete a large number of packaging tasks in a short time.

2. Accuracy: Equipped with advanced measurement and control systems, it can accurately control the filling volume of each bottle of sauce to ensure product consistency and stability. High-precision filling operation reduces the waste of sauce and improves resource utilization.

3. Intelligent: Integrated with intelligent control system and sensor technology, it can monitor various parameters in the filling process in real time, such as filling speed, filling volume, temperature, etc. Through data collection and analysis, the equipment can automatically adjust filling parameters and optimize the production process.

4. Diversity: Modern fully automatic sauce packaging machines are highly adaptable and can fill sauces according to different specifications and types, adapting to various packaging containers, such as glass bottles, plastic bottles, metal cans, etc. Modular design makes equipment adjustment and maintenance more convenient.

5. Hygiene: Food production has extremely high hygiene requirements. The fully automatic sauce packaging machine uses materials and designs that meet food-grade standards to ensure the cleanliness and hygiene of the equipment. The automatic cleaning function further ensures the hygienic status of the equipment and avoids cross-contamination.

Fully automatic sauce packaging machines are widely used in the food processing industry, especially in the following fields with significant advantages:

1. Condiment production: suitable for filling and packaging of various condiments, such as tomato sauce, chili sauce, sesame sauce, etc.

2. Catering industry: The catering industry uses fully automatic sauce packaging machines to package sauces to meet the needs of different specifications and capacities and improve work efficiency.

3. Food processing plants: Small and medium-sized food processing plants introduce fully automatic sauce packaging machines to improve production efficiency and product quality, and enhance market competitiveness.

4. Family food production: Some family workshops or small food companies use fully automatic sauce packaging machines to fill their own sauces to increase the added value of their products.

Advantages of fully automatic sauce packaging machine

1. Improve production efficiency: The fully automatic sauce packaging machine can realize continuous, high-speed filling and packaging operations, significantly improving production efficiency. The traditional manual packaging method is inefficient and difficult to meet the needs of large-scale production, while automated equipment can complete a large number of packaging tasks in a short time to meet market demand.

2. Improve product quality: Equipped with advanced measurement and control systems, the fully automatic sauce packaging machine can accurately control the filling volume to ensure the consistency and stability of each bottle of sauce. High-precision filling operations reduce human errors and improve product quality and market competitiveness.

3. Enhance production safety: Food production has strict requirements on hygiene and safety. The fully automatic sauce packaging machine uses materials and designs that meet food-grade standards to ensure the cleanliness and hygiene of the equipment. The automatic cleaning function and multiple safety protection devices further ensure the safety and hygiene of the production process and reduce the risk of contamination.

4. Reduce production costs: Although the initial investment of a fully automatic sauce packaging machine is relatively high, its efficient production capacity and low operating costs significantly reduce the overall production cost. Automated equipment reduces dependence on labor, lowering labor costs and management costs. In addition, efficient filling and precise control reduce the waste of sauce and improve resource utilization.

5. Improve production flexibility: Modern fully automatic sauce packaging machines are highly flexible and can quickly adjust and switch according to different sauce types and packaging needs. By changing molds, adjusting parameters and upgrading software, the equipment can adapt to various specifications and types of sauce production needs and meet the diverse needs of the market.

The fully automatic sauce packaging machine is leading the transformation of the sauce production industry with its high efficiency, accuracy, intelligence and flexibility. It has significant advantages in improving production efficiency, improving product quality, enhancing production safety and reducing production costs, and has become an important means for modern sauce production companies to enhance their market competitiveness. With the continuous advancement of technology, fully automatic sauce packaging machines will continue to develop, bringing more innovation and opportunities to the sauce production industry. In the future, fully automatic sauce packaging machines will continue to play an important role in promoting sauce production towards efficient, intelligent and sustainable development.