Release Date:2024-06-24 12:59:16 Popularity:

With the continuous advancement of science and technology and the diversification of market demands, modern manufacturing is facing unprecedented challenges and opportunities. In order to stand out in the fierce market competition, companies are seeking more efficient and flexible production methods. As a tailor-made solution, automated production line customization can significantly improve an enterprise's production efficiency, product quality and market response speed, and has become an important driving force for the development of modern manufacturing. This article will explore in detail the advantages of automated production line customization and its important applications in various industries.

Definition of automated production line customization

Automated production line customization refers to the design and manufacture of specialized automated production lines based on the company's specific production needs and process flow. It comprehensively uses multi-disciplinary technologies such as machinery, electrical, control, and computers to realize the automation and intelligence of the production process through the integration of automation equipment and systems. Customized production lines can fully meet the individual needs of enterprises, optimize the production process, and improve production efficiency and product quality.

The main advantages of automated production line customization

1. Improve production efficiency: Customized automated production lines can design the optimal production process and layout according to the specific production needs of the enterprise, minimizing ineffective links and time waste in production. The efficient operation of automated equipment greatly improves production efficiency. For example, in the automobile manufacturing industry, customized automated production lines can realize rapid assembly and inspection of vehicles, increase production speed, and shorten production cycles.

2. Improve product quality: The customized design of automated production lines can ensure precise control of every production link and reduce errors and quality problems caused by human operations. High-precision automation equipment and advanced control systems can realize real-time monitoring and feedback of product quality, ensuring product consistency and stability. For example, in electronic product manufacturing, customized production lines can achieve high-precision assembly and testing of precision components, improving product reliability and performance.

3. Reduce production costs: Although the initial investment in customized automated production lines is relatively high, its efficient production capacity and low operating costs significantly reduce the overall production costs. The continuous operation and efficient production of automated equipment reduce dependence on labor and reduce labor costs and management costs. At the same time, customized design can optimize the utilization of raw materials, reduce waste, and improve the economic benefits of production. For example, in the food processing industry, customized production lines can achieve efficient utilization of raw materials and reduce production costs.

4. Enhance production flexibility: Customized automated production lines can quickly adjust production processes and processes according to changes in market demand, and flexibly respond to the production needs of different products. Through modular design and flexible configuration, the production line can adapt to the production of products of various specifications and shapes, improving the company's market response speed and competitiveness. For example, in the packaging industry, customized production lines can quickly adjust packaging specifications and forms to meet the needs of different customers.

5. Improve operational safety: The customized design of automated production lines can fully consider the safety of operators and be equipped with various safety protection devices and systems, such as safety doors, emergency stop buttons, photoelectric protection, etc., to ensure the safety of the production process. The use of automated equipment reduces the frequency and intensity of manual operations, reduces the risk of safety accidents that may occur during operation, and improves the safety and comfort of the working environment. For example, in chemical production, customized automated production lines can realize automation and remote control of dangerous operations and improve production safety.

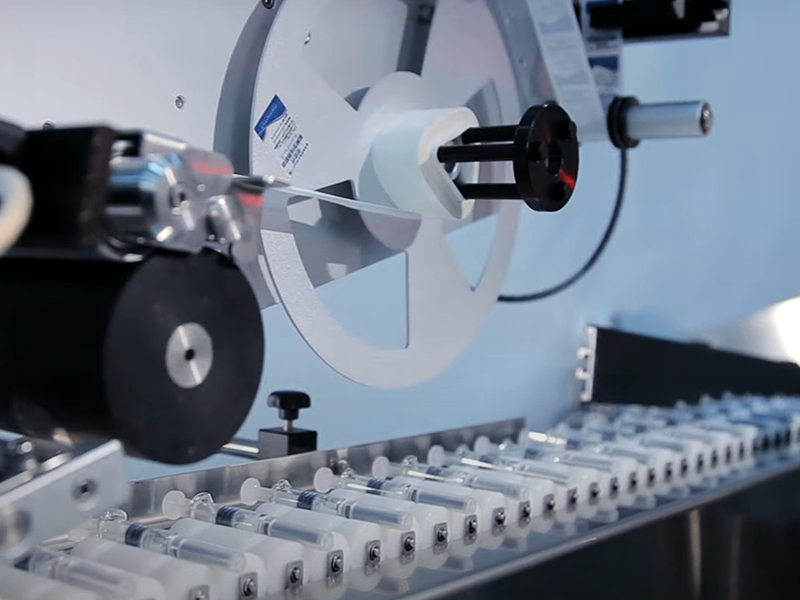

6. Data monitoring and management: Customized automated production lines are usually equipped with advanced data collection and monitoring systems, which can monitor various data in the production process in real time, and record and analyze it. Enterprises can use these data to optimize and improve the production process and improve production efficiency and product quality. At the same time, data accumulation and analysis can also provide scientific basis for enterprises' production decisions and promote intelligent management of enterprises. For example, in the pharmaceutical industry, customized production lines can realize full data monitoring and traceability of the production process, improving the scientificity and effectiveness of production management.

Automated production line customization is widely used in various industries. The following are some main application areas:

1. Automobile manufacturing: Customized automated production lines are used in automobile assembly, welding, painting and testing to improve production efficiency and product quality.

2. Electronic manufacturing: In the electronic manufacturing industry, customized production lines are used for the assembly, testing and packaging of electronic components to ensure high precision and high reliability of products.

3. Food processing: Customized production lines in the food processing industry are used for food production, packaging and testing, improving production efficiency and product quality, and ensuring food safety and hygiene.

4. Pharmaceutical industry: Customized production lines in the pharmaceutical industry are used for the production, packaging and testing of drugs to ensure the safety and effectiveness of drugs and meet strict quality control requirements.

5. Chemical production: Customized production lines in chemical production are used for the production, packaging and testing of various chemical products to improve production efficiency and safety and ensure product quality and consistency.

The development direction of automated production line customization

1. Intelligence and digitalization: With the development of Industry 4.0, automated production line customization will become more intelligent and digital. By introducing Internet of Things (IoT) and artificial intelligence (AI) technologies, production lines can achieve intelligent monitoring, predictive maintenance and production optimization, improving the intelligence level of equipment.

2. Modular design: Future automated production line customization will be more modular and can be quickly adjusted and upgraded according to different production needs, improving the flexibility and production efficiency of the production line.

3. Green environmental protection and energy saving: Environmental protection and energy saving will become important directions for future automated production line customization. The production line will use more environmentally friendly materials and energy-saving technologies to reduce energy consumption and environmental pollution and promote the development of green manufacturing.

4. High precision and high speed: As the market's demand for high quality and high efficiency continues to increase, automated production line customization will develop in the direction of higher precision and higher speed, improving production efficiency and product quality.

5. Human-machine collaboration and safety: Human-machine collaborative robots will be widely used in automated production lines. Combined with artificial intelligence and sensing technology, human-machine collaboration equipment will enable more efficient and safer production operations, improving production efficiency and the safety of the working environment.

With its high efficiency, flexibility and accuracy, automated production line customization is leading the development trend of modern manufacturing. It has significant advantages in improving production efficiency, improving product quality, reducing production costs, enhancing production flexibility and improving operational safety, and has become an important means for enterprises to enhance market competitiveness. With the continuous advancement of technologies such as intelligence, digitization, modularization, environmental protection and human-machine collaboration, automated production line customization will continue to develop, bringing greater economic benefits and market competitiveness to enterprises. In the future, automated production line customization will continue to play an important role in promoting various industries to move towards efficient, intelligent and sustainable development.