Release Date:2024-06-22 13:24:01 Popularity:

With the rapid development of the global economy and the continuous advancement of technology, the manufacturing industry is facing increasingly fierce competition. In order to improve production efficiency, reduce costs and improve product quality, companies have introduced automated packaging equipment. With its high efficiency, accuracy and flexibility, automated packaging equipment is gradually replacing traditional manual packaging methods and becoming the mainstream choice for modern industrial packaging. This article will explore the advantages of automated packaging equipment in detail, revealing its important role and broad prospects in various industries.

Definition of automated packaging equipment

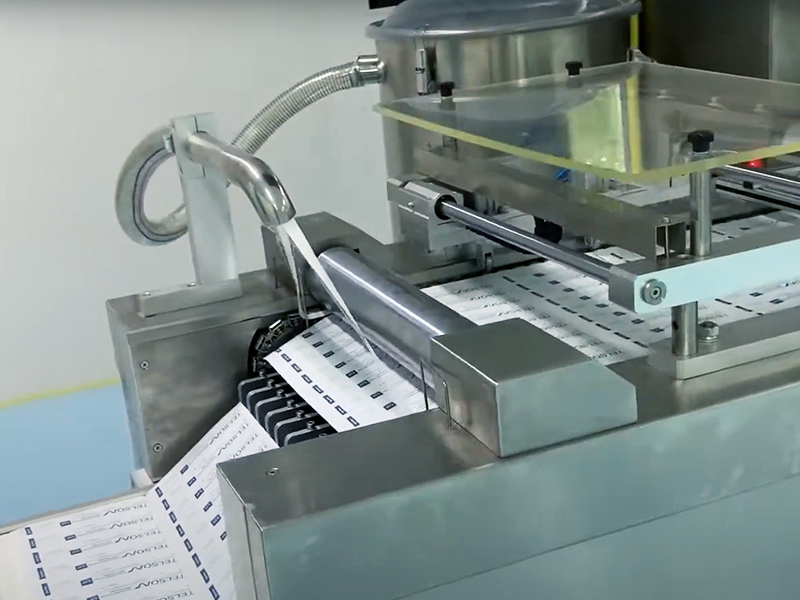

Automated packaging equipment refers to equipment that uses mechanical, electrical, optical and computer technologies to automate the product packaging process. It covers a series of processes from product sorting, conveying, filling, sealing, labeling, palletizing to final packaging inspection. Through the application of automation technology, packaging efficiency and packaging quality are improved.

The main advantages of automated packaging equipment

1. Improve production efficiency: Automated packaging equipment can complete various packaging processes continuously and at high speed, significantly improving production efficiency. Compared with traditional manual packaging, automated equipment can significantly shorten packaging time and meet the needs of mass production. For example, the automatic packaging assembly line can complete the packaging task of thousands of products in a short time, greatly improving the production capacity of the enterprise.

2. Improve product quality: Automated packaging equipment has a high degree of accuracy and consistency, ensuring that the quality of each package meets standard requirements. Through a sophisticated control system, the equipment strictly controls various parameters in the packaging process, such as temperature, pressure, speed, etc., to reduce errors and defects caused by human operation, thereby improving the overall quality of the product.

3. Reduce production costs: Although the initial investment in automated packaging equipment is relatively high, its efficient production capacity and low labor costs significantly reduce overall production costs. Automated equipment can reduce dependence on labor and reduce labor costs, while improving the utilization rate of raw materials and reducing waste. In addition, the stable operation of equipment can also reduce losses and rework costs caused by human operating errors.

4. Enhance production flexibility: Modern automated packaging equipment has strong flexibility and can quickly adjust and switch according to the packaging needs of different products. By changing molds and adjusting parameters, the equipment can adapt to product packaging needs of various specifications and shapes, meet the diversified needs of the market, and improve the market competitiveness of enterprises.

5. Improve operational safety: Automated packaging equipment reduces the frequency and intensity of manual operations and reduces the risk of safety accidents that may occur during the operation. The equipment is equipped with various safety protection devices, such as safety doors, emergency stop buttons, photoelectric protection, etc., to ensure the safety of operators. At the same time, the use of automated equipment can also reduce workers’ labor intensity and improve the safety and comfort of the working environment.

6. Data monitoring and management: Modern automated packaging equipment is usually equipped with a data collection and monitoring system, which can monitor various data in the packaging process in real time, and record and analyze it. Enterprises can use these data to monitor and optimize the production process, discover and solve problems in a timely manner, and improve production efficiency and product quality. At the same time, data accumulation and analysis can also provide scientific basis for enterprises' production decisions and promote intelligent management of enterprises.

Automated packaging equipment is widely used in various industries. The following are some main application areas:

1. Food and beverage: In the food and beverage industry, automated packaging equipment is used for packaging various foods and beverages, such as bottled beverages, bagged foods, canned foods, etc., to ensure the hygiene and quality of the products.

2. Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for packaging. Automated equipment is used for bottling, boxing and bagging of medicines to ensure the safety and effectiveness of medicines.

3. Cosmetics and daily chemicals: Cosmetics and daily chemicals products have high requirements for the appearance of packaging. Automated equipment can achieve high-quality packaging and improve the market appeal of the products.

4. Electronic products: The packaging of electronic products requires high precision and efficiency. Automation equipment is used for packaging of electronic components and finished products to ensure the precision and reliability of packaging.

5. Logistics and warehousing: In the logistics and warehousing industry, automated packaging equipment is used for packaging and packaging of various goods to improve logistics efficiency and packaging quality.

The development direction of automated packaging equipment

1. Intelligence and digitalization: With the development of Industry 4.0, automated packaging equipment will become more intelligent and digital. By introducing Internet of Things (IoT) and artificial intelligence (AI) technologies, equipment can achieve intelligent monitoring, predictive maintenance and production optimization, improving the intelligence level of equipment.

2. Modular design: Future automated packaging equipment will be more modular and can be quickly adjusted and upgraded according to different production needs, improving the flexibility and production efficiency of the equipment.

3. Environmental protection and energy saving: Environmental protection and energy saving will become important directions for the development of automated packaging equipment in the future. Equipment will use more environmentally friendly materials and energy-saving technologies to reduce energy consumption and environmental pollution and promote the development of green manufacturing.

4. High precision and high speed: As the market's demand for high quality and high efficiency continues to increase, automated packaging equipment will develop towards higher precision and higher speed, improving production efficiency and product quality.

5. Human-machine collaboration and safety: Human-machine collaborative robots will be widely used in automated packaging equipment. Combining artificial intelligence and sensing technology, human-machine collaboration equipment will enable more efficient and safer production operations, improving production efficiency and the safety of the working environment.

With its high efficiency, precision and flexibility, automated packaging equipment is leading the development trend of modern industrial packaging. It has significant advantages in improving production efficiency, improving product quality, reducing production costs, enhancing production flexibility and improving operational safety, and has become an important means for enterprises to improve market competitiveness. With the continuous advancement of technologies such as intelligence, digitization, modularization, environmental protection and human-machine collaboration, automated packaging equipment will continue to develop, bringing greater economic benefits and market competitiveness to enterprises. In the future, automated packaging equipment will continue to play an important role in promoting various industries to move towards efficient, intelligent and sustainable development.