Release Date:2024-06-13 18:47:31 Popularity:

In the rapid development of modern manufacturing industry, fully automatic packaging equipment is playing an increasingly important role as a key equipment to improve production efficiency, reduce costs and ensure product quality. This article will discuss in detail the working principle, main features, advantages and application of fully automatic packaging equipment in various industries, and look forward to its future development trend.

The working principle of fully automatic packaging equipment. Fully automatic packaging equipment realizes the full process automation operation from product feeding, metering, packaging, sealing to finished product output through integrated automation technology. Its basic work flow includes:

1. Feeding system: The product to be packaged is transported to the feeding port of the packaging equipment through conveyor belts, vibrating feeders and other equipment.

2. Measuring system: Use high-precision sensors and metering equipment to accurately measure the product to ensure that the weight or quantity of each package of products meets the preset standards.

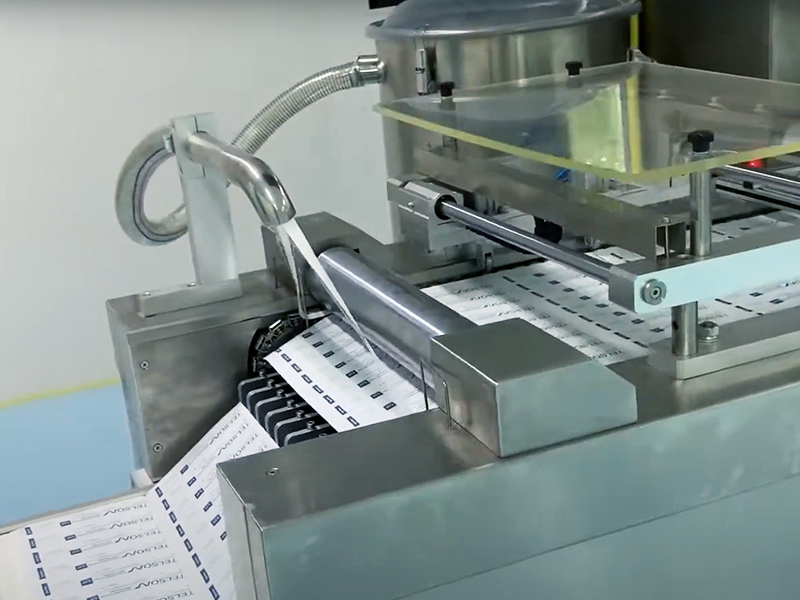

3. Packaging molding: Automatic packaging equipment molds packaging materials (such as plastic film, paper box, etc.) into bags, boxes and other packaging containers.

4. Filling and sealing: Fill the measured product into the formed packaging container and seal the package by heat sealing, bonding and other methods.

5. Finished product output and inspection: After packaging, the finished product is output through the conveyor belt and the quality is checked by the inspection system. Unqualified products will be automatically rejected.

Main features of fully automatic packaging equipment

1. High efficiency: Fully automatic packaging equipment can perform packaging operations continuously and at high speed, greatly improving production efficiency.

2. High precision: Advanced metering and control systems are used to ensure that the weight or quantity of each package of products is accurate.

3. Intelligence: Equipped with PLC control system and human-machine interface (HMI), operators can complete parameter settings and operations through the touch screen and monitor the operating status of the equipment in real time.

4. Multi-function: The equipment integrates multiple functions such as feeding, metering, packaging, sealing, and inspection, which can complete integrated operations and improve packaging efficiency.

5. Wide range of applications: Applicable to multiple industries such as food, beverages, medicine, chemicals, and electronics to meet the packaging needs of different products.

Advantages of fully automatic packaging equipment

1. Improve production efficiency: Fully automated operation significantly improves packaging speed, reduces manual intervention and waiting time, and greatly improves production efficiency.

2. Ensure product quality: High-precision metering and control systems ensure that the weight or quantity of each package of products is consistent, avoiding product quality problems caused by uneven packaging.

3. Reduce production costs: By reducing material waste and labor costs, fully automatic packaging equipment helps companies effectively reduce production costs and improve economic benefits.

4. Improve safety and hygiene: The equipment design meets industry hygiene and safety standards, reduces the chance of manual contact with products, and reduces pollution and safety hazards.

5. Enhance market competitiveness: Efficient and precise packaging capabilities improve product consistency and aesthetics, and enhance the competitiveness of corporate products in the market.

Application areas of fully automatic packaging equipment

1. Food industry: In the food industry, fully automatic packaging equipment is widely used in the packaging of rice, flour, candy, chocolate, biscuits and other products. Its efficient packaging capabilities and strict hygiene standards ensure the safety and quality of food.

2. Beverage industry: The beverage industry has high requirements for packaging speed and precision. Fully automatic packaging equipment can quickly and accurately complete the packaging of bottled water, juice, carbonated beverages and other products, improving production efficiency and product quality.

3. Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for packaging accuracy and cleanliness. Fully automatic packaging equipment can meet the packaging needs of products such as medicines and health products to ensure the safety and effectiveness of medicines.

4. Chemical industry: In the chemical industry, fully automatic packaging equipment is used for the packaging of powders, granules, and liquid chemicals to ensure accurate measurement and safe packaging of materials.

5. Electronics industry: The packaging of electronic products requires high precision and high protection. Fully automatic packaging equipment can meet the packaging needs of products such as electronic components and circuit boards to ensure the safe transportation and storage of products.

Development trend of fully automatic packaging equipment

1. Intelligence and digitalization: In the future, fully automatic packaging equipment will further develop in the direction of intelligence and digitalization. By integrating Internet of Things (IoT) technology and big data analysis, equipment can achieve remote monitoring, maintenance and optimization, improve production efficiency and equipment utilization.

2. Environmental protection and sustainability: With the increase of environmental awareness, fully automatic packaging equipment will pay more attention to the use of environmentally friendly materials and the improvement of energy efficiency. Equipment manufacturers will develop more environmentally friendly and sustainable solutions to reduce the impact on the environment.

3. Multifunctionality and flexibility: In order to meet the diverse market demands, fully automatic packaging equipment will develop in the direction of multifunctionality and flexibility. The equipment will have stronger adaptability and can be quickly adjusted to meet the needs of different products and packaging forms.

As an important equipment for modern industrial production, fully automatic packaging equipment has significantly improved production efficiency and product quality with its high efficiency, precision and intelligence. In many fields such as food, beverages, medicine, chemicals, and electronics, fully automatic packaging equipment has shown a wide range of application prospects. With the continuous advancement of science and technology and changes in market demand, fully automatic packaging equipment will continue to play its important role and promote various industries to move towards efficiency, intelligence and sustainable development. By introducing and optimizing fully automatic packaging equipment, enterprises can not only enhance their own market competitiveness, but also better meet the needs of consumers and achieve sustainable development.