Release Date:2024-06-04 11:26:33 Popularity:

In modern industrial production, automated production lines have become an important means for enterprises to improve production efficiency, ensure product quality and reduce costs. With the diversification and personalization of market demand, standardized automated production lines can no longer fully meet the needs of enterprises. Automated production line customization services have emerged and become an important tool for enterprises to gain advantages in fierce market competition. This article will explore the significance, advantages and applications of automated production line customization in various industries.

The significance of automated production line customization

Automated production line customization refers to tailoring automated equipment and systems suitable for the production characteristics of an enterprise according to its specific production needs and process flow. This customized service not only includes the design and manufacture of hardware equipment, but also covers the development and integration of software systems to achieve full process automation from raw materials to finished products.

Advantages of automated production line customization

1. Meet personalized needs: The production process and product characteristics of each enterprise are different, and standardized automated production lines often cannot fully adapt. Through customized services, enterprises can design production lines according to their own needs, ensure that the equipment is highly compatible with the production process, and maximize the efficiency of the equipment.

2. Improve production efficiency: Customized production lines can optimize the production process, reduce unnecessary links and waiting time, and thus significantly improve production efficiency. At the same time, the efficient operation of automated equipment also reduces the errors and downtime caused by manual operation.

3. Ensure product quality: Through precise control and real-time monitoring, customized production lines can ensure product consistency and quality stability. The automated system can perform quality inspections during the production process, promptly discover and correct problems, and reduce the defective rate.

4. Reduce production costs: Although the initial investment of customized production lines is high, by improving production efficiency, reducing labor costs and reducing scrap rates, it can significantly reduce production costs and improve the economic benefits of enterprises in the long run.

5. Flexibly respond to market changes: Customized production lines are highly flexible and can quickly adjust and adapt to changes in market demand. Enterprises can quickly adjust production plans and product specifications based on market feedback and order requirements to improve market response speed and competitiveness.

Application areas of customized automated production lines

1. Automobile manufacturing: The automobile manufacturing industry requires highly complex and precise production processes. Through customized automated production lines, enterprises can realize full process automation from parts manufacturing to vehicle assembly, improve production efficiency and product quality, and meet the production needs of different models and specifications.

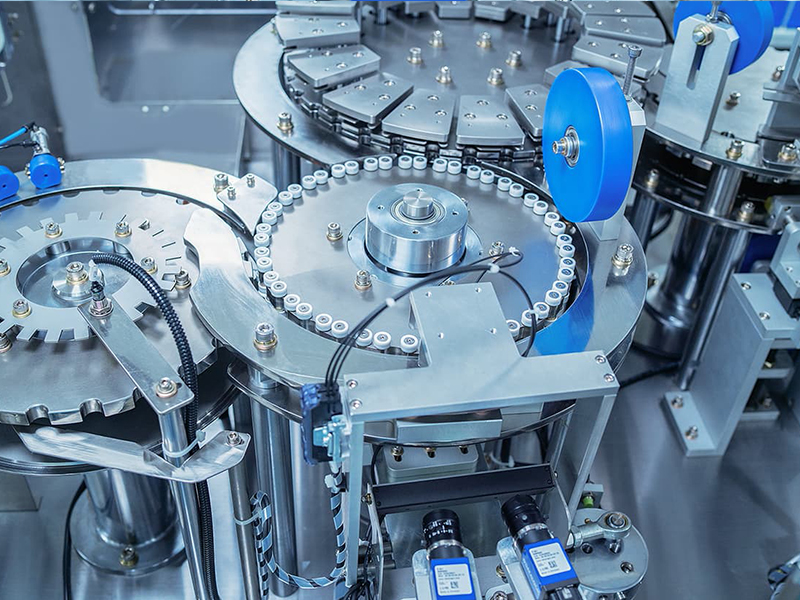

2. Electronic products: The production process of electronic products is complex and requires extremely high precision. Customized production lines can achieve precision assembly, welding and testing to ensure the quality and performance of each product and adapt to rapidly changing market demands.

3. Food and Beverage: The food and beverage industry has extremely high requirements for hygiene and production efficiency. Through customized production lines, companies can achieve automated raw material processing, production, packaging and testing to ensure product safety and quality, and improve production efficiency and capacity.

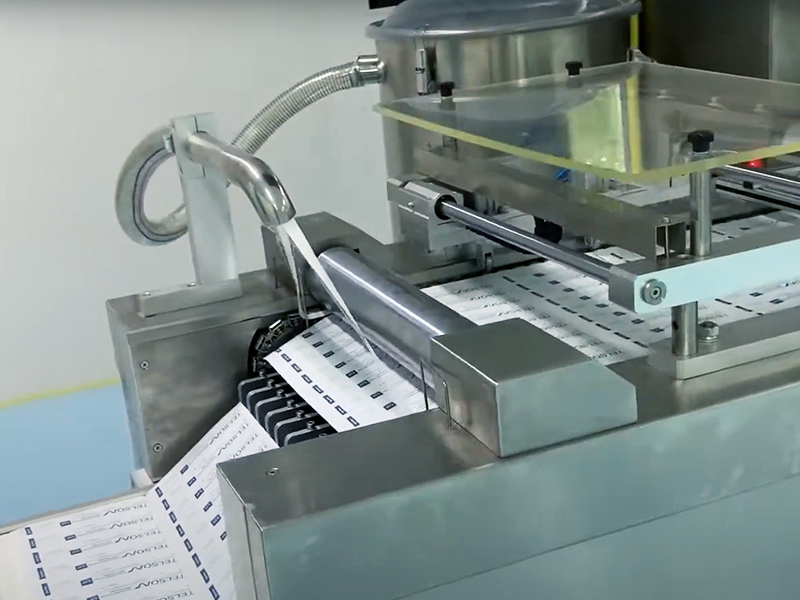

4. Pharmaceutical industry: Pharmaceutical production has extremely high requirements for the environment, equipment and process. Customized production lines can meet strict hygiene standards and production specifications, realize automated drug manufacturing, packaging and testing, and ensure the safety and effectiveness of drugs.

5. Home appliance manufacturing: The home appliance industry has a wide variety of products and complex production processes. Customized production lines can design corresponding production equipment and process flows according to the characteristics of different products to achieve efficient production and assembly and meet the diverse needs of the market.

Implementation steps for customized automated production lines

1. Demand analysis: First, companies need to conduct detailed demand analysis to clarify production processes, product characteristics and production goals. Fully communicate with automation equipment suppliers to determine the functions and specifications of customized production lines.

2. Scheme design: According to the results of demand analysis, the equipment supplier conducts scheme design to determine the layout, equipment configuration and process flow of the production line. The enterprise works closely with the supplier to ensure that the design scheme meets the actual needs.

3. Equipment manufacturing: After the design scheme is determined, it enters the equipment manufacturing stage. The supplier produces the equipment according to the design requirements, and assembles and debugs it to ensure that the equipment performance and quality meet the requirements.

4. Installation and debugging: After the equipment is manufactured, it is installed and debugged on site. The supplier dispatches technicians to install and debug to ensure the normal operation of the production line, and conducts trial production to test the performance and stability of the production line.

5. Training and after-sales service: The supplier trains the enterprise's operators to ensure that they master the operation and maintenance methods of the production line. At the same time, provide comprehensive after-sales service to ensure the long-term and stable operation of the production line.

As an important means of modern industrial production, the customization of automated production lines has significantly improved the production efficiency and market competitiveness of enterprises with its high efficiency, precision and flexibility. In many fields such as automobile manufacturing, electronic products, food and beverages, medicine and home appliance manufacturing, the customization of automated production lines has shown a wide range of application prospects. With the continuous advancement of technology and changes in market demand, automated production line customization will continue to play an important role in promoting various industries to move towards efficiency, intelligence and sustainable development. By introducing and optimizing automated production line customization, enterprises can not only enhance their market competitiveness, but also better meet consumer needs and achieve sustainable development.